Dear Mr. Electrician: What are the actual electrical conduit hole saw sizes for the various trade sizes of electrical conduit?

Answer: Electrical conduit hole saw sizes and knockout punch sizes for conduit are posted below.

NOTE: Some text links below go to applicable products on Amazon. As an Amazon Associate, I earn from qualifying purchases. Using my Links helps to keep this website FREE.

Electrical conduit hole saw sizes are not the exact dimensions as the trade name size of the conduit.

Table of Contents:

- Drilling With A Hole Saw

- Hole Saw Sizes and Knockout Punch Equivalent

- Hole Sizes for Tapping Conduit Threads

- Knockout Punch Operating Instructions

- Greenlee Knockout Punch Replacement Part Numbers

DRILLING WITH A HOLE SAW

When drilling with a hole saw, it is important to use a slower-spinning drill with a lot of torque rather than a high-speed drill. It is best to drill at 400 revolutions per minute (RPM) or slower when using a hole saw.

Drilling at a slower speed will help the hole saw last longer, and there is less danger of getting jammed and causing damage or injury.

I usually use my 1/2″ Milwaukee Electric Right Angle Drill when using a larger hole saw as the torque is very good, and the RPMs are just right. The extra length of the right-angle drill makes it easier to maintain control of the drill if the hole saw does get jammed.

I suggest wearing work gloves when using a right-angle drill. Some angle drills have an accessory handle to gain extra leverage and control when drilling. It is a good idea to use it.

When drilling into metal, it is a good idea to oil the hole saw a few times during the drilling process to prevent premature wearing of the hole saw teeth. I read in a trade magazine of one electrician who puts an oil-soaked cut-to-size piece of Felt inside his hole saws whenever he drills into metal. As the hole saw heats up from drilling, the oil will trickle down onto the drilled metal.

Put something on the floor to protect it from oil leaks, such as flattened boxes or an old piece of plywood. Although you can probably use most general-purpose or motor oils for lubricating when drilling, there are oils made especially for drilling, tapping, and threading. Amazon sells cutting oil, which is used for these purposes.

At the bottom of this post is a list of old Greenlee hand knockout punch replacement part numbers that I scanned.

CLICK HERE to see Electrician’s Hole Saw Kits on Amazon

The above photo depicts two types of hole saw arbors that are not interchangeable. The three arbors on the top left can only be used with a hole saw that has a rectangular, round shape. The others screw into one of two standard-size threads on hole saws with threads.

HOLE SAW SIZES AND KNOCKOUT PUNCH EQUIVALENT

1/2″ conduit, drill using a 7/8″ or 22mm hole saw. 1/2″ conduit knockout punch is 0.885″ or 22.5mm.

3/4″ conduit, drill using a 1 1/8″ or 29mm hole saw. 3/4″ conduit knockout punch is 1.115″ or 28.3mm.

1″ conduit, drill using a 1 3/8″ or 35mm hole saw. 1″ conduit knockout punch is 1.362″ or 34.6mm.

1 1/4″ conduit, drill using a 1 3/4″ or 44mm hole saw. 1 1/4″ conduit knockout punch is 1.701″ or 43.2054mm.

1 1/2″ conduit, drill using a 2″ or 51mm hole saw. 1 1/2″ conduit knockout punch is 1.951″ or 49.6mm.

2″ conduit, drill using a 2 1/2″ or 64mm hole saw. 2″ conduit knockout punch is 2.416″ or 61.3664mm.

2 1/2″ conduit, drill using a 3″ or 76mm hole saw. 2 1/2″ conduit knockout punch is 2.914″ or 74mm.

3″ conduit, drill using a 3 5/8″ or 92mm hole saw. 3″ conduit knockout punch is 3.539″ or 89.9mm.

3 1/2″ conduit, drill using a 4 1/8″ or 104mm hole saw. 3 1/2″ conduit knockout punch is 4.044″ or 102.7mm.

4″ conduit, drill using a 4 1/2″ or 114mm hole saw. 4″ conduit knockout punch is 4.544″ or 115.4176mm.

5″ conduit, use a 5 1/2″ or 140mm hole saw.

6″ conduit, use a 6 5/8″ or 168mm hole saw.

HOLE SIZES FOR TAPPING CONDUIT THREADS

| Electrical Conduit Trade Size, Not the Actual Dimensions | Drill Size For Conduit or Fitting | Drill Size For NPT Tapered Tap. Taper is 3/4"per foot. | Threads Per Inch |

|---|---|---|---|

| 1/8" Pipe or Fixture Nipple (NPS) | 13/32" | Q (21/64" or 0.332"), (NPS 0.348" S) | 27 Threads Per inch |

| 1/4" Pipe or Fixture Nipple (NPS) | 35/64" | 7/16" (NPS 29/64") | 18 Threads Per Inch |

| 3/8" Pipe or Fixture Nipple (NPS) | 43/64" | 9/16" (NPS 19/32") | 18 Threads Per Inch |

| 1/2" or 16mm Conduit (NPS) | 7/8" or 22mm | 45/64" (NPS 47/64") | 14 Threads Per Inch |

| 3/4" or 21mm Conduit (NPS) | 1 1/8" or 28mm | 59/64" or 7/8" (NPS 15/16") | 14 Threads Per Inch |

| 1" or 27mm Conduit (NPS) | 1 3/8" or 35mm | 1 5/32" (NPS 1-3/16") | 11.5 Threads Per Inch |

| 1 1/4" or 35mm Conduit | 1 3/4"or 44mm | 1 1/2" | 11.5 Threads Per Inch |

| 1 1/2" or 41mm Conduit | 2" or 51mm | 1 47/64" | 11.5 Threads Per Inch |

| 2" or 53mm Conduit | 2 1/2" or 64mm | 2 7/32" | 11.5 Threads per Inch |

| 2 1/2" or 63mm Conduit | 3" or 76mm | 2 5/8" | 8 Threads per Inch |

| 3" or 78mm Conduit | 3 5/8" or 92mm | 3 1/4" | 8 Threads per Inch |

| 3 1/2" or 91mm Conduit | 4 1/8" or 104mm | 3 3/4" | 8 Threads per Inch |

| 4" or 103mm Conduit | 4 1/2" or 114mm | 4 1/4" | 8 Threads per Inch |

| 5" or 129mm Conduit | 5 1/2" or 140mm | 5 9/32" | 8 Threads per Inch |

| 6" or 155mm Conduit | 6 5/8" or 168mm | 6 11/32" | 8 Threads per Inch |

CLICK HERE to See Pipe Taps on Amazon

Knockout punches can be an alternative to electrical conduit hole saw sizes. You would drill a pilot hole sized for the draw stud of the punch using a step drill or a small hole saw. Then, use a hand knockout punch or a hydraulic knockout punch to make the desired size hole.

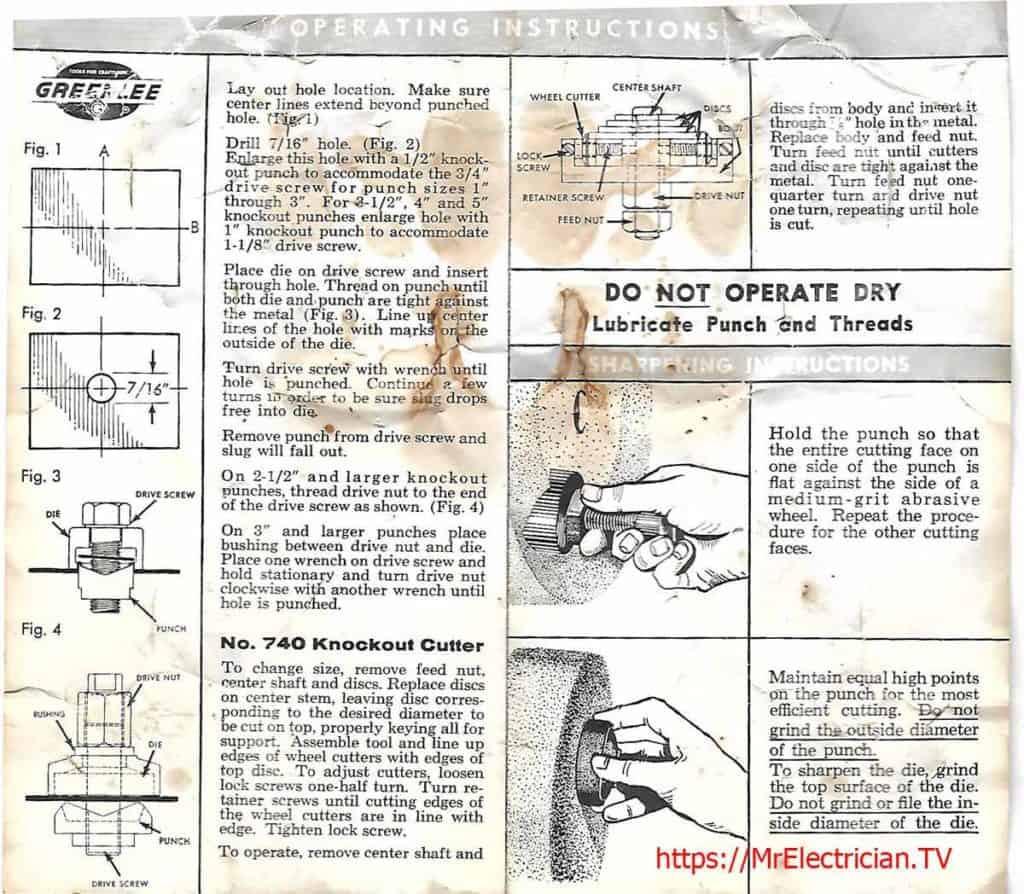

KNOCKOUT PUNCH OPERATING INSTRUCTIONS

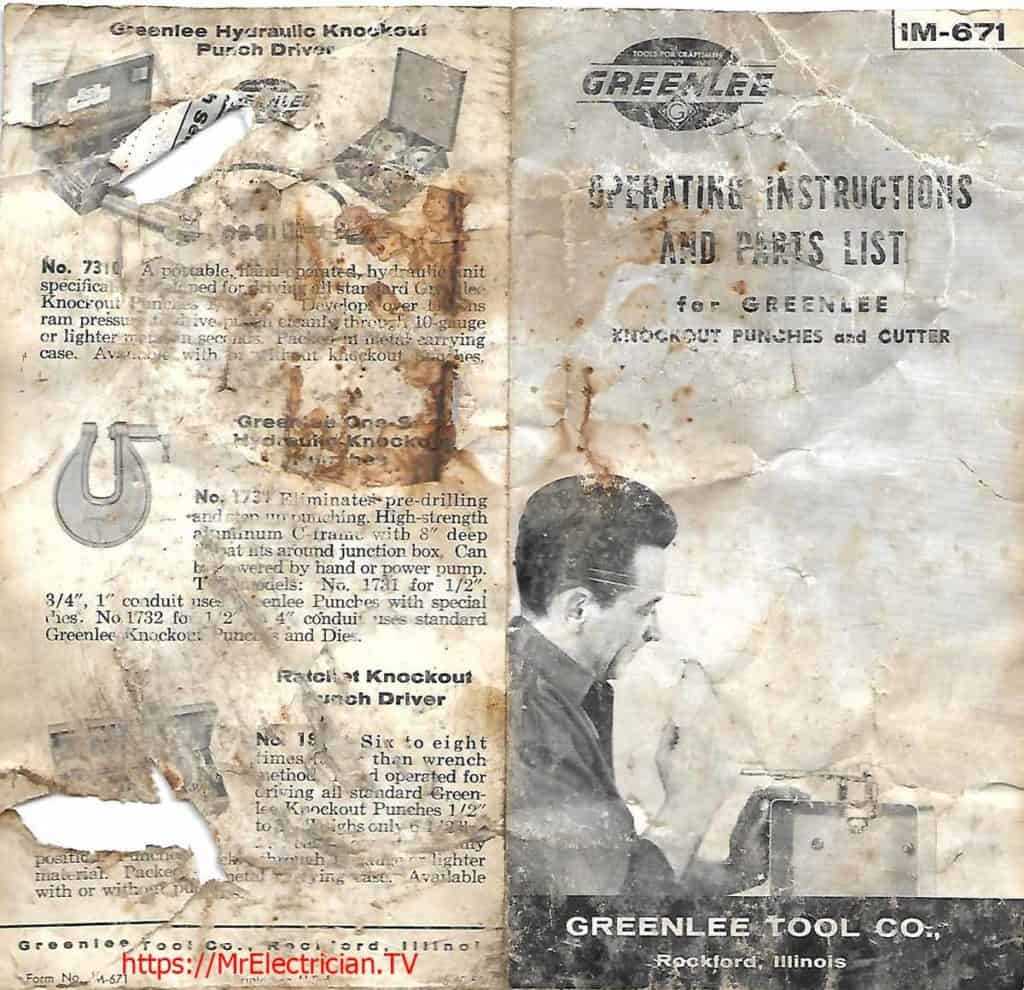

I found old knockout punch instructions with a parts list among my father’s tools. I scanned it and broke it up into sections for easier viewing. The paper is not in the best condition, as I surmise it is from the early 1960s.

Below are the operating instructions for Greenlee electrician’s hand knockout punches.

CLICK HERE to see Greenlee Knockout Punches on Amazon

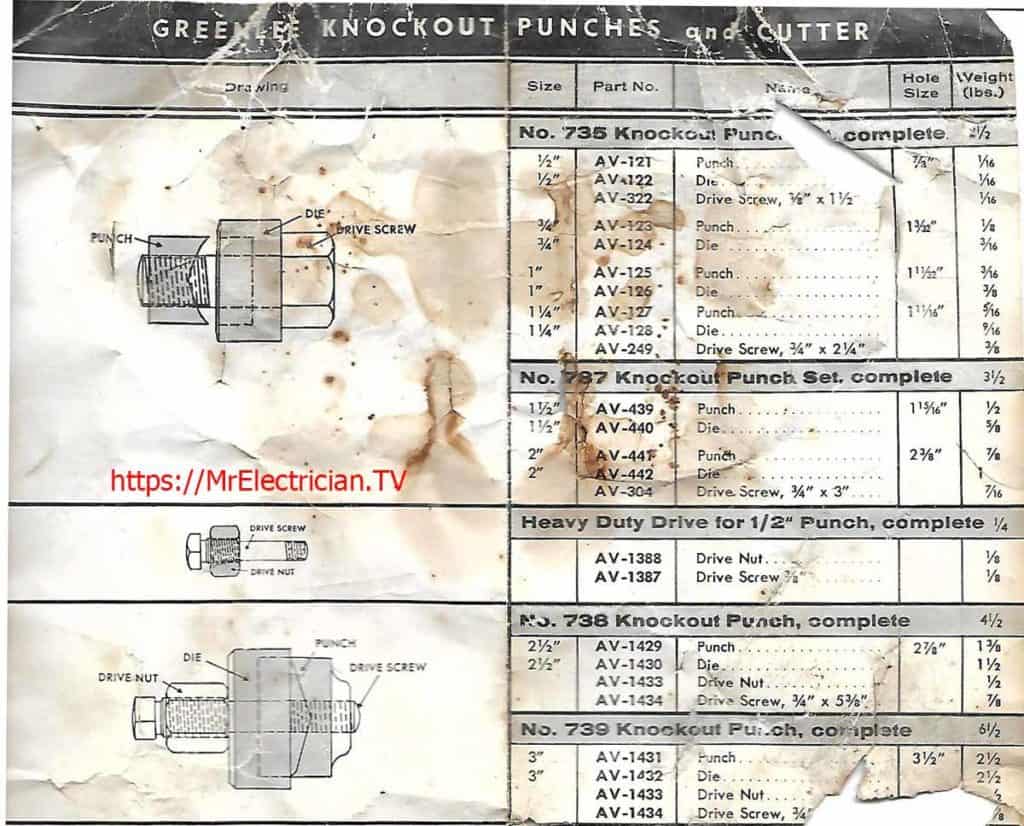

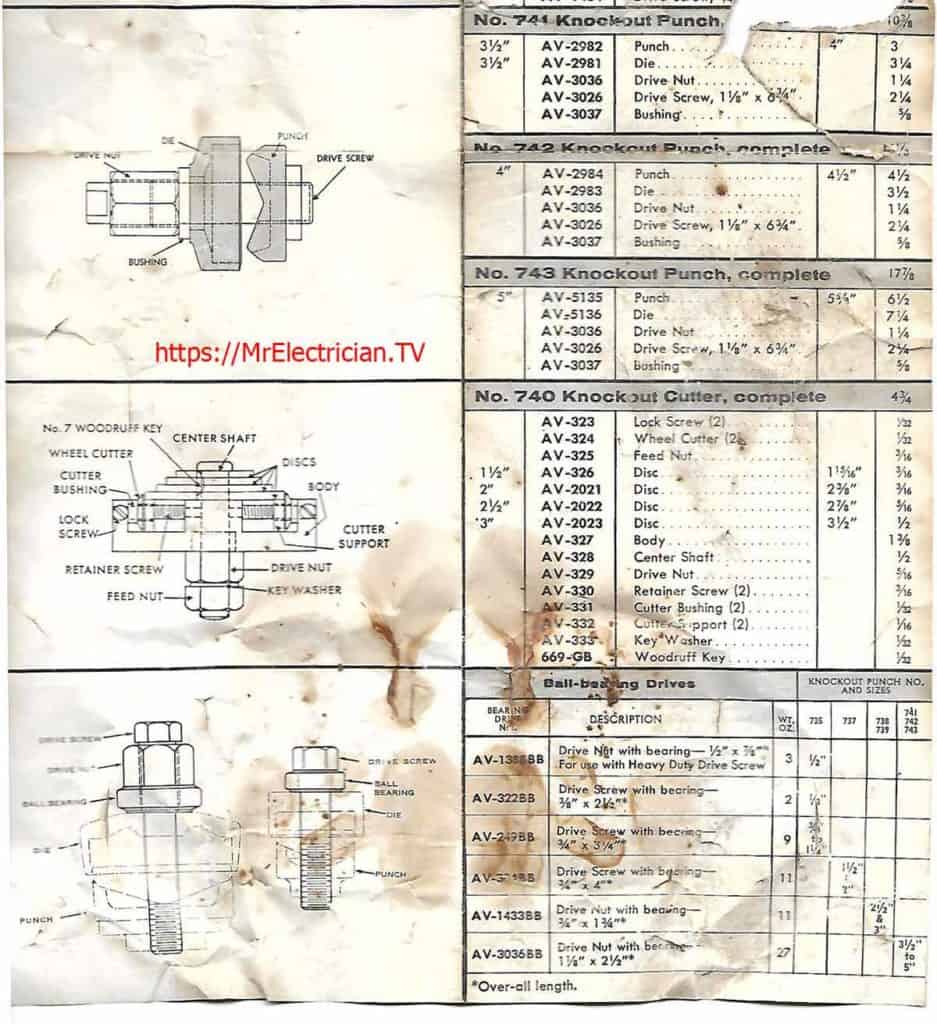

GREENLEE HAND KNOCKOUT PUNCH REPLACEMENT PART NUMBERS

The following two images depict the replacement part numbers for Greenlee hand knockout punches. I do not know how useful they will be today for obtaining replacement parts for Greenlee knockout punches.

In addition, the hole size of each knockout punch is provided.

Listed above are the dimensions of the knockout punch parts and their Greenlee part numbers.

The dimensions of the knockout punch parts and their Greenlee part numbers are depicted above.

The front and rear pages of the Greenlee Knockout Punch Operating Instructions and Parts List are below.

Click for my blog post on descriptions of a variety of electrical conduits.

All of the categories of electrical topics discussed by Mr. Electrician can be seen by clicking here.

If you need an OEM replacement part for commercial or industrial equipment, you may find the IQS Directory of Suppliers and Manufacturers helpful.

LINKS TO CONDUIT MANUFACTURERS

Aluminum and Steel Conduit Products – https://www.westerntube.com/

Fiberglass Conduit Products – https://championfiberglass.com/

PVC Conduit products – https://www.cantexinc.com/

Steel Conduit Products – https://www.alliedeg.us/

To help keep this website free, please use this Amazon link for your purchases. As an Amazon Associate, I earn from qualifying purchases.

Click for a FREE copy of my book “Almost Everything You Need To Know To Repair a Bathroom Exhaust Fan In Your Home.”

Get your required “Emergency Disconnect, Service Disconnect” labels and stickers to satisfy the 2023 National Electrical Code requirements in article 230.85(E)(1) by going to my Redbubble Shop here.

Visit my Link Tree for my social media accounts, more free electrical information, and unique products.

Visit my Electrician Tools Page for unique tool information.