Dear Mr. Electrician: What is the reason for Arc Fault Circuit Interrupters or AFCI?

Answer: Arc Fault Circuit Interrupters provide an additional level of protection against fires. Electrical arcs create heat and sparks. If combustible materials are nearby, a fire could erupt. Arc Fault Circuit Interrupter circuit breakers protect us from potential fire starters we cannot see.

Table of Contents:

- Types of Arc Faults

- Causes of Arc Faults

- Other Issues That Cause Arc Faults

- AFCI Trip Indicator Guide

NOTE: Some text links below go to applicable products on Amazon. As an Amazon Associate, I earn from qualifying purchases. Using my links helps to keep this website FREE.

Many residential homes have wood frame construction. The walls’ electrical switch and receptacle boxes are attached to wood framing members. The electrical wiring runs through the wood framing. Wood is a combustible material. If heat and sparks develop inside the wall, you will not know it until it becomes obvious.

An early warning indicator for possible loose connections is blinking or flickering lights. If you see lights flickering fairly regularly, you may have a loose connection somewhere or something else is going wrong. Have a professional electrician look into it for you.

TYPES OF ARC FAULTS DETECTED BY ARC FAULT CIRCUIT INTERRUPTERS

A Series Arc or low current arc can be as a result of frayed power cords, old appliances, or loose electrical connections.

A Parallel Arc or high current arc can occur from a screw or nail being partially driven into a live wire, causing a poor connection to be made between two current-carrying conductors. Also known as a line-to-neutral arc.

Line-To-Ground Arc or ground fault indicates electrical current leaking to earth ground.

A combination Arc Fault Circuit Interrupter will protect against the three types of arcs. However, a combination AFCI will not have GFCI protection. You need a dual-function circuit breaker for both AFCI AND GFCI protection.

CAUSES OF ELECTRICAL ARC FAULTS

An electrical arc can be caused by lightning, of course, and your grounding electrode system should handle that if it is in good condition.

However, other arcing causes are usually not as obvious until some damage or a fire occurs. For instance, an electrical receptacle with a loose connection may be fine until one winter, you decide to plug a high-wattage portable electric heater into it.

The heater uses a lot of current to keep you warm. With the extra LOAD on the electrical circuit, the loose connection that was working fine for a few years now arcs each time the heater is on.

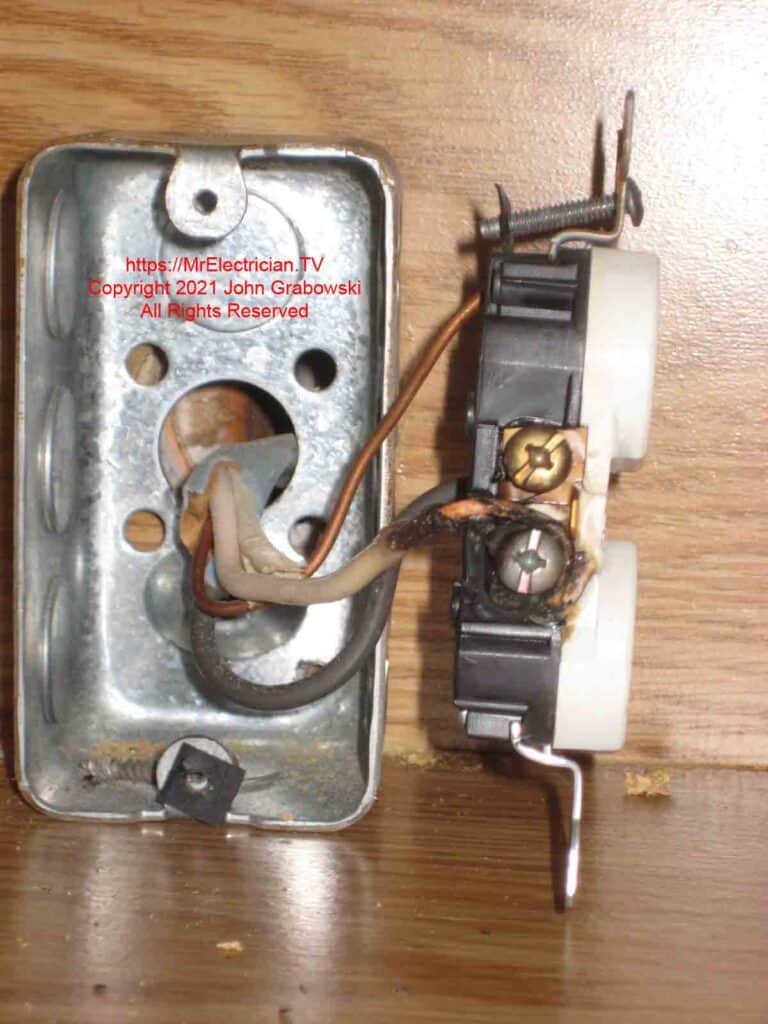

I found the above electrical outlet inside a kitchen cabinet for the over-the-range microwave oven. It was not installed by someone qualified. In addition to the loose connection that caused the arcing and subsequent burning, there was no connector in the back of the box to protect the cable from the edges of the metal electrical box. The knockout was punched out but is still attached to the box.

The electrical box was also not grounded properly. A ground wire connection should have been directly attached to the metal box. Instead, the ground wire only connects to the electrical outlet.

Something else that was a code violation, the electrical box was not screwed to the cabinet. It was just floating.

An Arc Fault Circuit Interrupter circuit breaker would have tripped off long before the damage got this far.

Arcing creates heat and sparks, which can cause damage to the electrical receptacle, the wiring in the electrical box and wall, and even the heater plug. In addition, the potential for fire is high. If combustible materials are nearby, such as drapes and curtains, bedding, or even furniture, a fire can start whether you are home or not.

OTHER ISSUES THAT CAN CAUSE ARC FAULTS AND HEAT

– Loose or broken plugs or cords on appliances and lamps.

– Nicks in the house wires and/or the wire insulation that occurred during the original construction or after renovation. A nail driven into the wall to hang a painting can nick a wire.

– Worn-out electrical receptacles that do not hold the plugs in tightly.

– Frayed insulation on appliances and lamps.

– Worn electrical switches.

– Very old electrically powered tools and appliances with degraded internal electrical insulation.

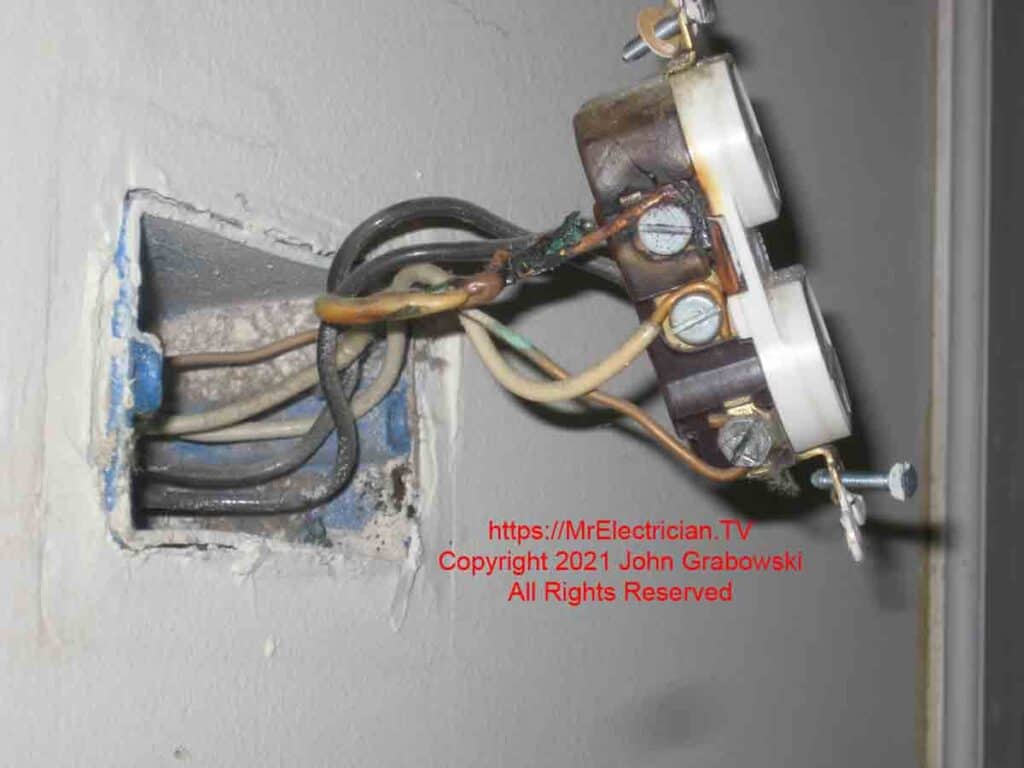

In the photo above, the homeowner replaced the existing electrical receptacle with an outlet with a different color. Not being a professional electrician, he was unaware of the torquing requirements for the screw terminals. He also put the ground wire backward on the green screw. The hook on the wire should close as the screw tightens in the clockwise direction.

With that much heat, sometimes the plastic electrical boxes get damaged and must also be replaced.

Another possibility for wiring getting damaged is from a major redecoration or renovation project where the old existing wiring is disturbed. A small unnoticed problem during the original renovation may not manifest itself into a major hazard until months or years later. Existing wiring is best left alone in older houses.

Like everything else in a house, wiring ages whether you use it or not. However, this does not mean you should replace every wire in your house after so many years. The wiring should last the life of the house as long as it is not disturbed, and minor maintenance, such as tightening connections, is performed every few years.

Maintenance, such as tightening all connections in the circuit breaker panel and at all switches and receptacles, will help to prevent arcing and heat. It is required that you torque all electrical connections according to factory specifications. A torque screwdriver is used for that purpose.

All wiring devices and electrical equipment are accompanied by installation instructions or labeling that mention the torque requirements. Torqueing is done with a torque wrench or a torque screwdriver, depending on the device or equipment.

Pigtailing electrical receptacle outlets is better than feeding through each outlet to reduce arcing. When a receptacle outlet is pigtailed, the full circuit LOAD is not being carried through the receptacle, not just the LOAD for that receptacle.

Top Of Page

ARC FAULT CIRCUIT INTERRUPTER TRIP INDICATOR GUIDE

Some Arc Fault Circuit Interrupters circuit breakers have built-in diagnostic codes to help figure out why an AFCI circuit breaker tripped.

On Siemens one pole AFCI circuit breakers if LEDs A and B trip indicators are both off, it was an overcurrent condition that caused the breaker to trip. With LED A on and LED B off, it was an arc fault. If both LED A and B are on after the Siemens one pole AFCI trips, that indicates an arc fault to ground.

Siemen’s two-pole AFCI trip indicators are slightly different. Three yellow lights off indicate an overcurrent condition. Yellow light 1 on indicates an arc fault on phase A. Yellow light 3 on indicates an arc fault on phase B. All three yellow lights on indicate an arc fault to ground.

Cutler Hammer Type CH Arc Fault Circuit Interrupters circuit breakers (Tan handle) have blinking lights to indicate the cause of the circuit breaker trip. 1 blink indicates a series arc. Two blinks are for a parallel arc. 3 blinks indicate a short delay. 4 blinks are for overvoltage. 5 blinks indicate a ground fault. 6 blinks mean a self-test failure, and the AFCI breaker should be replaced. No blinking lights after the breaker has tripped means an overload or a short circuit.

Eaton Type BR AFCI circuit breaker also has a blinking light to indicate the type of condition that caused it to trip. No blinking light is an overload or short circuit. One blink is a low current arc. Two blinks is a high current arc. Three blinks mean a short delay. Four blinks is for overvoltage. Six blinks indicate a self-test failure, and the breaker should be replaced.

Square D AFCI trip indication is a little different. On Type QO and Type Homeline Arc Fault Circuit Interrupter circuit breakers, after a breaker trips, push the Test button and turn the breaker back on simultaneously. If the breaker trips immediately after that it means a fault-to-earth ground. If the breaker trips again after a 2-second delay, that indicates a parallel or series arc fault. If the AFCI breaker trips after 5 seconds, there is a thermal overload or a short circuit.

For more reading on AFCIs and arc faults in general, see the Siemens website here.

Articles 210.12, 440.65, 550.25, and 406.4(D)(4) in the National Electrical Code pertain to the requirements for arc fault protection. Replacement electrical receptacles in existing homes must be tamper-resistant arc fault circuit interrupter receptacles.

Dual Function Circuit Breakers and receptacles are available. One dual-function circuit breaker or receptacle can provide arc fault circuit interrupter and ground fault protection for many receptacles.

Homes with original aluminum wiring installed in the 1970s should have already taken steps to prevent the excessive arcing that the old aluminum is known for. See my post on preventative measures for aluminum wiring by clicking here.

Click here to read my blog post about properly grounding outlets and switches.

To help keep this website FREE, please use this Amazon link for your purchases. As an Amazon Associate, I earn from qualifying purchases.

Click for a FREE copy of my book “Almost Everything You Need To Know To Repair a Bathroom Exhaust Fan In Your Home.”

Get your required “Emergency Disconnect, Service Disconnect” labels and stickers to satisfy the 2023 National Electrical Code requirements in article 230.85(E)(1) and (2) by going to my Redbubble Shop here.

Visit my Link Tree home page for my social media connections and other links.