Dear Mr. Electrician: Tell me how to ground an outlet.

Answer: Learning how to ground an outlet depends significantly on your wiring methods. For instance, plastic outlet boxes have different grounding requirements than metal outlet boxes.

NOTE: Some text links below go to applicable products on Amazon. As an Amazon Associate, I earn from qualifying purchases. Using my links helps to keep this website FREE.

Table of Contents:

- HOW TO GROUND AN OUTLET WITH NON-METALLIC CABLE

- GROUNDING SWITCHES AND OUTLETS WITH BX AND MC ARMORED CABLE

- GROUNDING WITH METAL CONDUIT

- SELF-GROUNDING SWITCHES AND OUTLETS

- OTHER GROUNDING METHODS

Anything made of metal in your home that has electricity flowing through it must be grounded. Some methods below can add a ground wire when changing from a two-prong to a three-prong outlet. Photos below show how to ground an outlet or a switch under various wiring conditions.

HOW TO GROUND AN OUTLET WITH NON-METALLIC CABLE

The uninsulated equipment grounding conductor inside the Type NM-B Non-Metallic Cable (Romex) must be connected to the grounding terminal bar at the power source, such as the main electrical panel.

The other end of the equipment grounding conductor must be connected to all metal boxes, switches, outlets, appliances, or equipment to create safer operating conditions while using electricity.

Only one wire can go under an outlet or switch’s green grounding screw terminal. All other equipment grounding conductors must be spliced with a grounding pigtail wire using an approved wire connector.

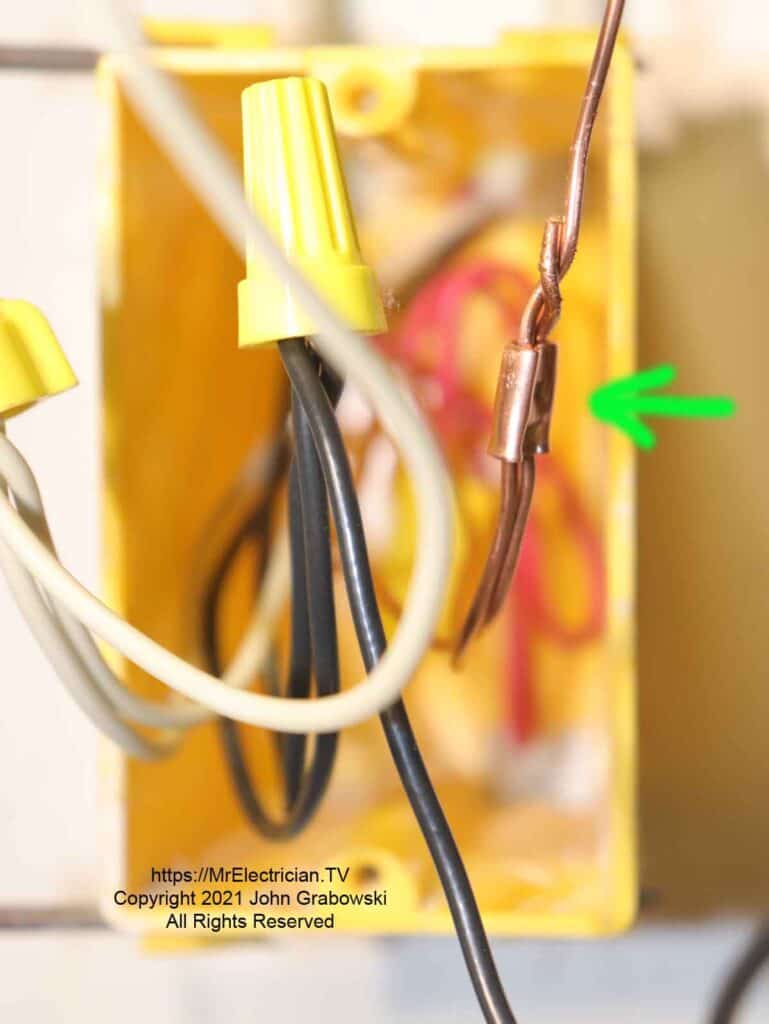

Crimp sleeves are used by many electricians when working on new installations to connect all of the equipment grounding conductors together along with a pigtail. When installed correctly, the crimps are a perfect ground connection.

Wires must be twisted tightly together before crimping. I use my Klein Linesman Pliers with the built-in crimping notch to make good solid crimps, and I don’t need to carry an extra tool.

The downside to crimped ground wires is that they are challenging to take apart if needed.

No code requirements exist to attach a ground wire to a non-metallic electrical box. Only metal boxes need to be grounded. However, the grounding wires in a plastic outlet or switch box should not be cut back so short that they are challenging to work with.

You must allow enough slack so that all wires in an electrical box are at least six inches (150mm) long (Article 300.14).

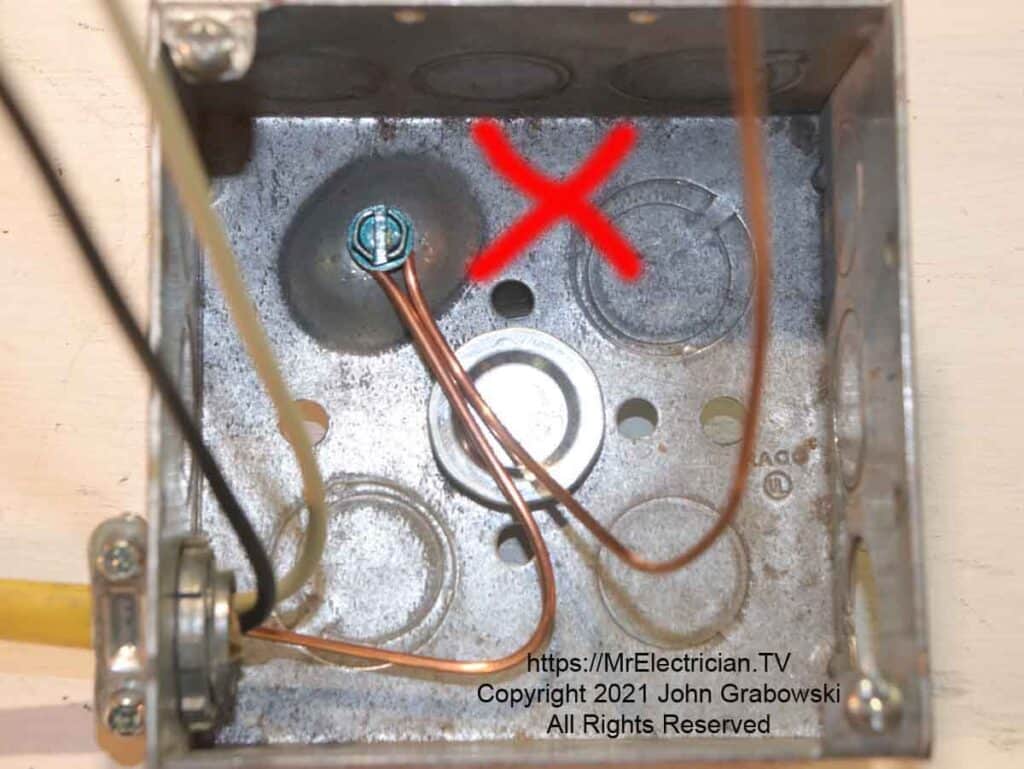

A metal electrical box must have a separate grounding pigtail connected to it, then connected to all the ground wires in that box. Looping the feed wire ground around the grounding screw and using the end for a pigtail connection has been disallowed, beginning with the 2020 National Electrical Code (NFPA 70) article 250.148(C).

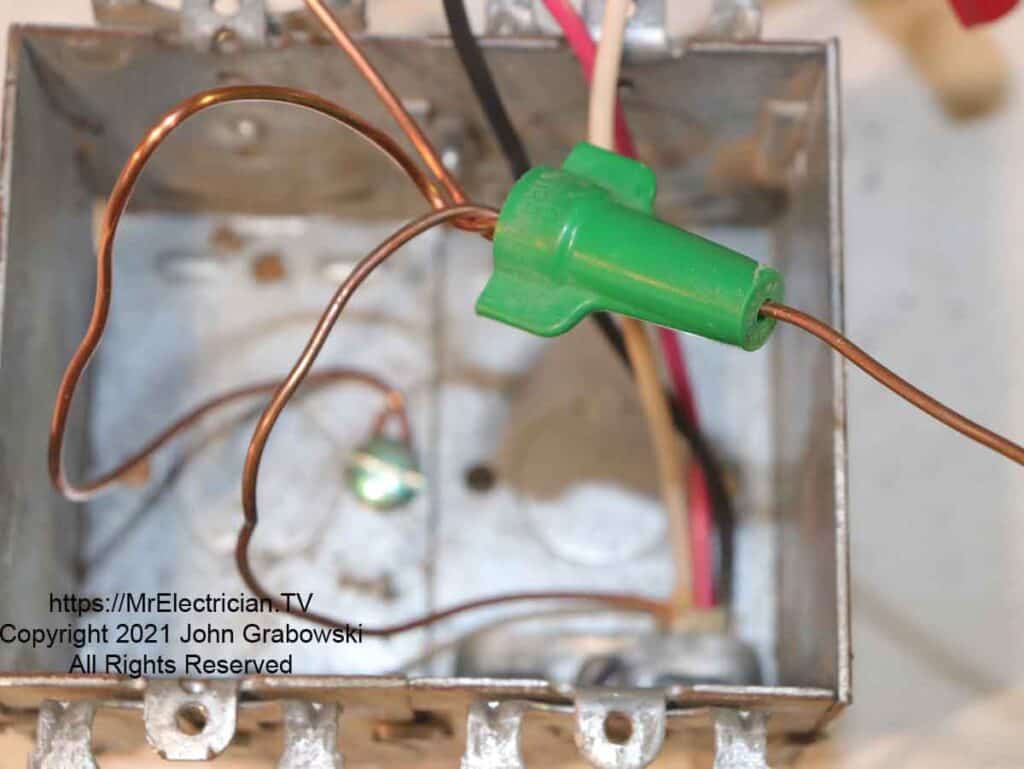

The green twist-on wire connectors are for grounding conductors only due to the pigtail hole in the top. They are very convenient for splicing wires with a pigtail.

One grounding conductor is left much longer than the others. The shorter wire ends are twisted around the longer wire using pliers, about six inches from the long end. Then, the green wire connector is twisted over the wires.

Several different manufacturers make green twist-on wire connectors.

Ground wires can be joined using standard wire connectors. There is no need to buy special connectors to connect copper ground wires and pigtails unless green connectors with the hole for a pigtail work better for your installation.

If you have a lot of ground wires that need splicing together, allow 2″ – 3″ for the twisting together. As the twisted group grows, each additional wire will use up more slack around the bunch. Use big wire connectors if necessary.

With so many wires to join, using the proper size wire connector is essential to keep them together. A wire connector that is too small will result in a loose connection. The packaging of wire connectors usually has a chart listing all the wire combinations for which a particular wire connector is approved.

Twist the wires together using pliers to ensure a good connection before twisting the wire connector on.

GROUNDING SWITCHES AND OUTLETS WITH BX AND MC ARMORED CABLE

Type AC cable (Commonly called BX) has a metal interlocking armored protective jacket around its wires. That metal armor is also the equipment grounding conductor for BX cable (Article 320.108). However, it must be installed correctly using the proper fittings to be an effective ground. BX connectors must be installed wrench tight.

Some BX cables have an equipment grounding conductor wire inside in addition to the grounding armor. Hospital BX cable is a green armored cable with an insulated grounding conductor inside. It is used primarily in hospital electrical circuits requiring more than one ground path.

Even though some BX cables may have a separate equipment grounding conductor, the armor must be properly terminated to ensure ground continuity.

The cable on the left above does not have an effective ground path. The BX connector is loose, and the BX cable is pulled out of the connector. The grounding pigtail connected to the electrical box can go under the green screw on an outlet or switch.

The internal metal bonding strip from the BX cable is pulled over the anti-short bushing and wrapped tightly around the armor to keep the bushing in place while inserted into the BX connector.

The internal lightweight metal bonding wire inside the BX cable is not an equipment grounding conductor. It is only to maintain grounding continuity inside of the BX. Connecting the internal bonding wire to any grounding conductors or terminal screws is unnecessary.

BX cable is not recommended for use with a plastic electrical box. However, when necessary, there is a solution to maintain ground continuity. Grounding continuity is maintained using a grounding bushing on the BX connector with a grounding pigtail. The pigtail from the grounding bushing is connected to all other grounding conductors in the electrical box.

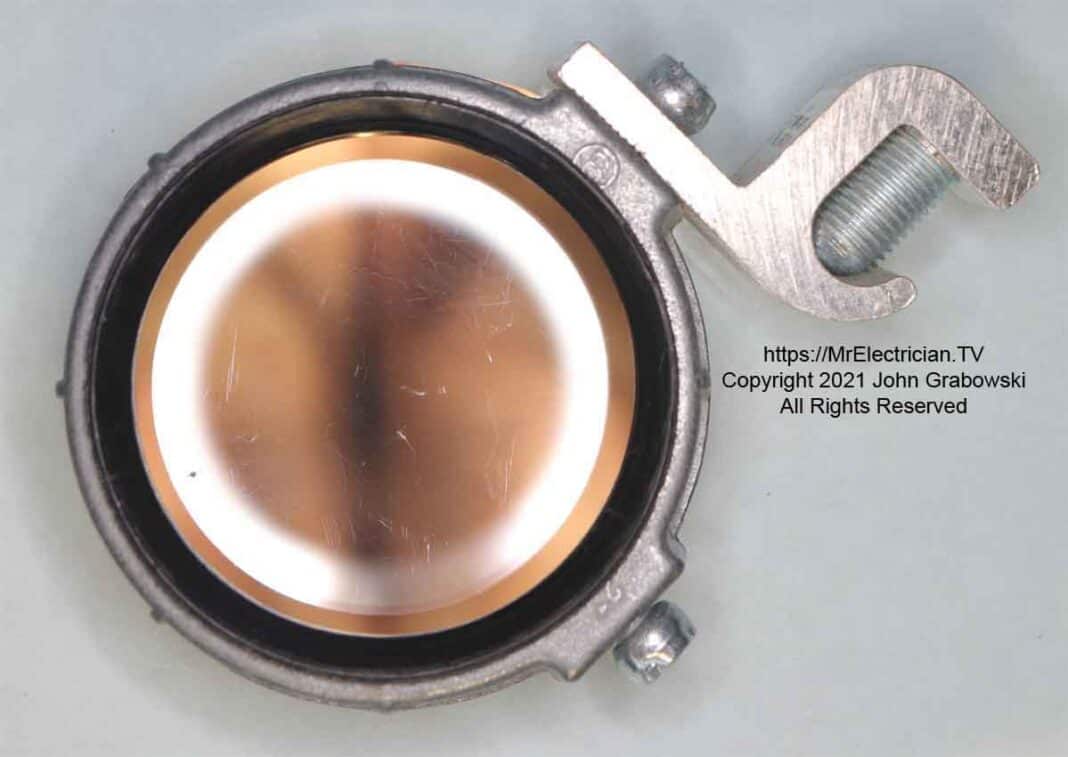

The half-inch grounding bushing is threaded onto the end of the BX connector, and a set screw is tightened down to lock it in place. The lay-in lug is removable, making it easy to screw the bushing on.

The BX connector must be secured with the locknut first before screwing the grounding bushing on. The grounding bushing has limited threads. Without the locknut, the BX connector would be loose.

Looking closely, you can see the little red tail from the anti-short bushing sticking out through the grounding bushing. This makes it easy for the electrical inspector to see that the installation complies with the electrical code.

Type MC cable also has a metal jacket but is not always an approved grounding conductor. Check the packaging or tags to see if your MC cable armor is an approved grounding conductor. MC has a separate green insulated equipment grounding conductor. However, the metal armor of the MC cable must still be grounded using approved MC cable connectors, which are not the same as BX connectors.

As with BX connectors, MC connectors must be installed wrench-tight. There are locknut wrenches for this. Also, Channellock pliers can be used. I use a hammer and an old screwdriver on large connectors to bang the locknuts tight.

Anti-short Bushings are used for all BX and MC cables and Flexible Metal Conduit to protect the wire insulation from getting nicked and causing a short circuit. I have seen a few instances where an anti-short bushing was not used, resulting in a short circuit to the metal armor.

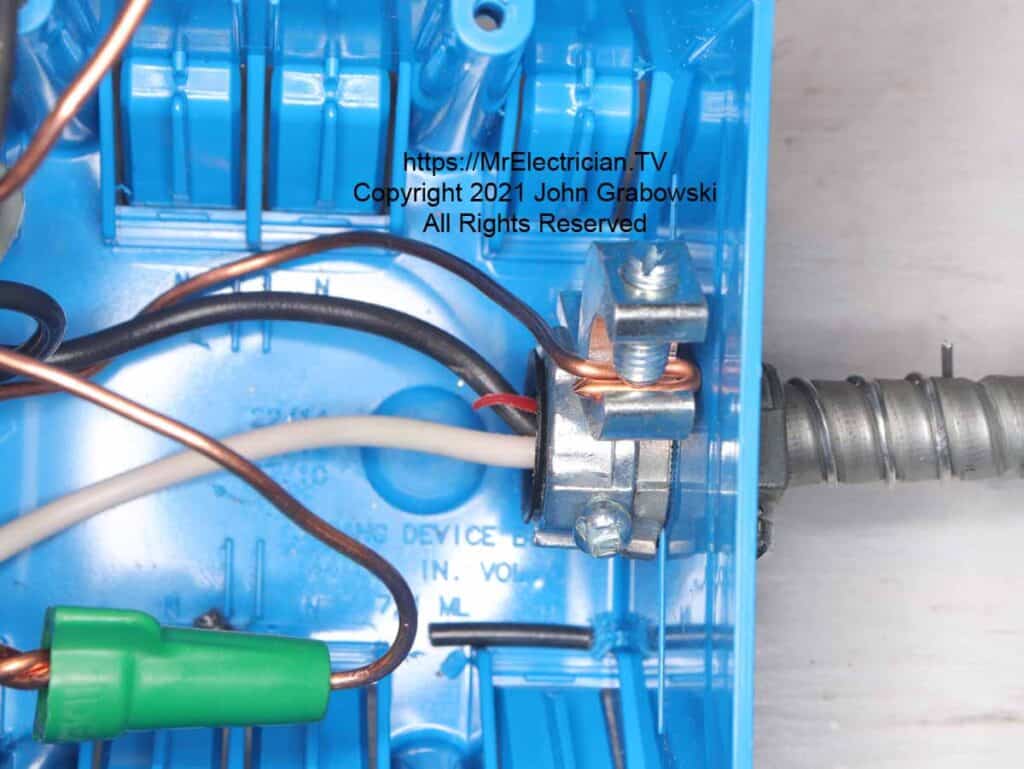

GROUNDING WITH METAL CONDUIT

As with BX and MC, the connectors, couplings, and other fittings for metal electrical conduits must be wrench-tight when installed to maintain an effective ground path. Fittings such as the conduit angle compression connector above must have its locknut wrench tight into the electrical box and the conduit’s compression ring. The pigtail on the metal box gets connected directly to the electrical outlet.

Read article 250.118 in the National Electrical Code (NFPA 70) for all approved equipment grounding conductors.

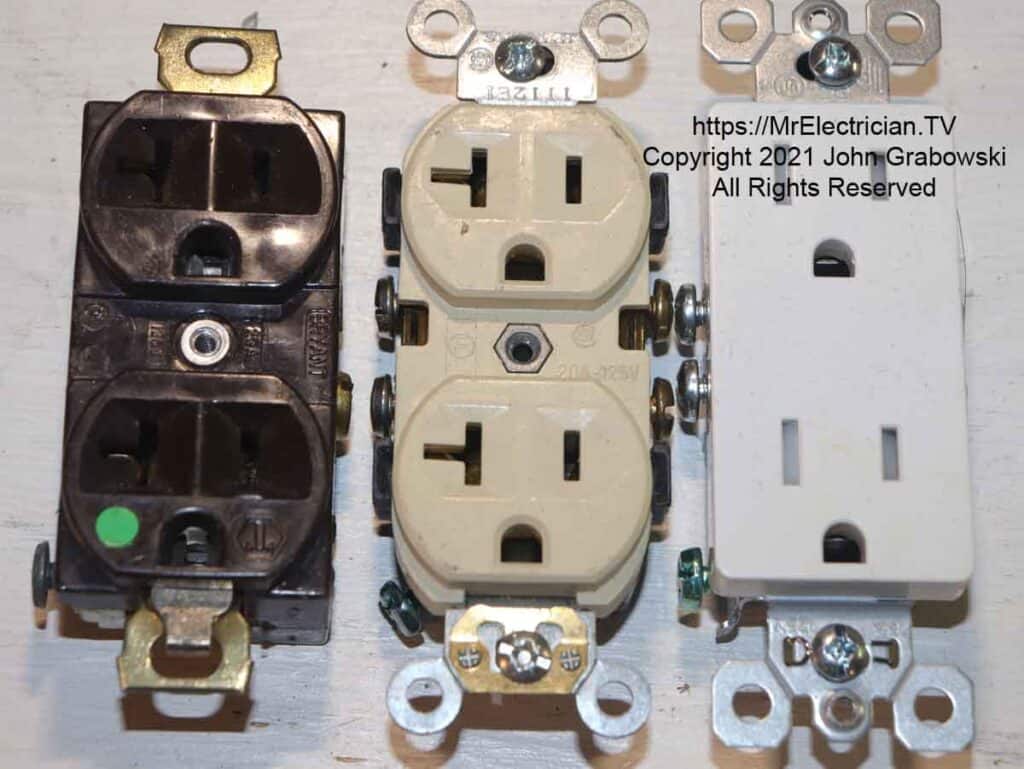

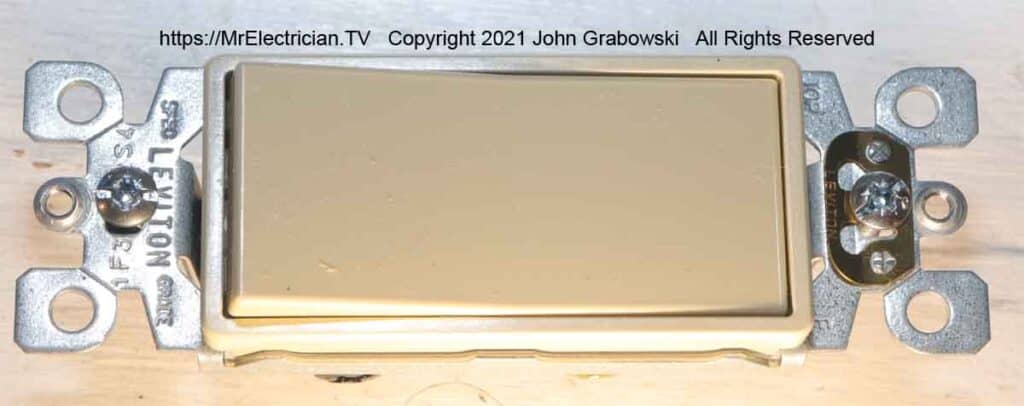

SELF-GROUNDING SWITCHES AND OUTLETS

With a grounded metal outlet box, self-grounding outlets can save some work. Self-grounding outlets are handy when replacing old, ungrounded two-prong outlets on a grounded system.

Self-grounding outlets do not create a ground. They automatically connect to the ground in an existing grounded metal box when installed. Self-grounding outlets have a little clip on one of the device support screws that maintain the ground connection as long as it is screwed into a grounded metal box.

Click here to see my post about replacing two-prong ungrounded outlets.

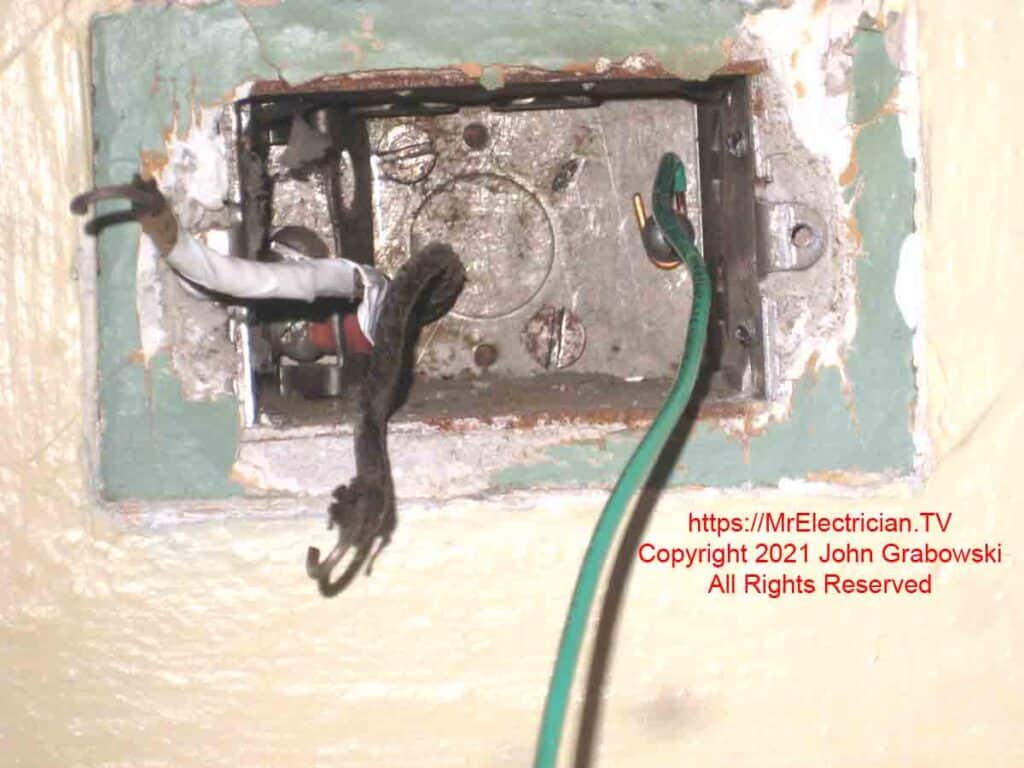

I removed a two-prong outlet from the above electrical box in the wall. The box was grounded through the old BX cable armor. I made sure that the cable clamp screw was tight. I added a ground screw and pigtail to an already tapped hole to have a ground wire for the new three-prong grounding outlet. I could have used a self-grounding outlet, but I did not have one handy then.

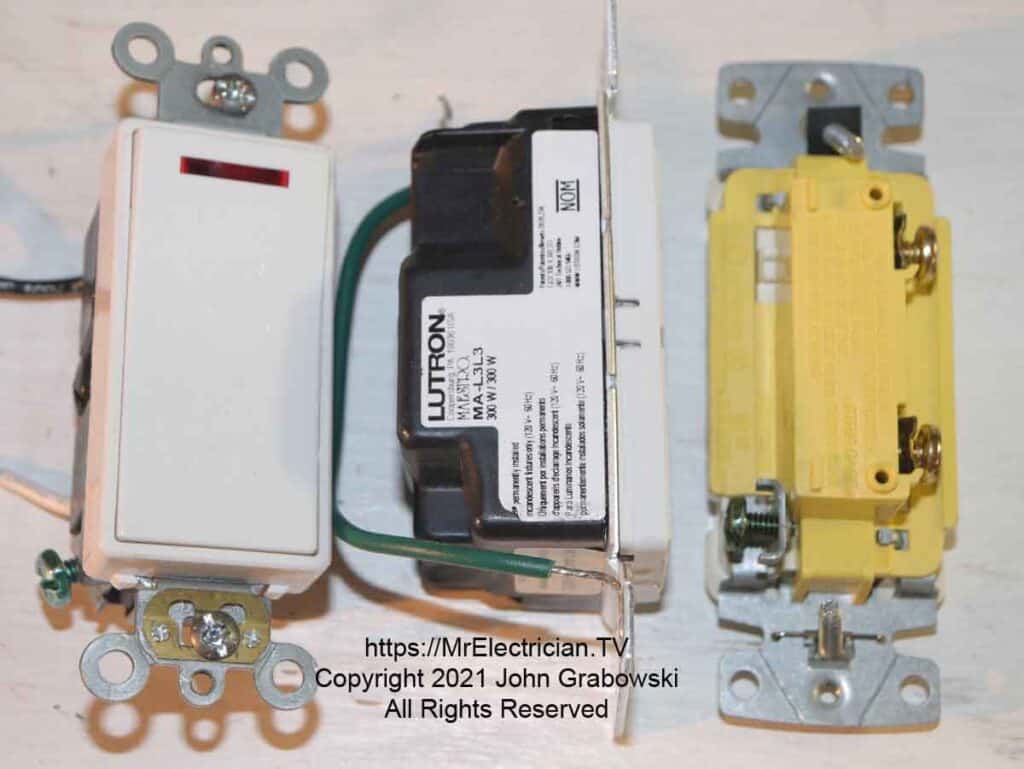

In the case of many dimmers and electronic controls, a grounding pigtail must be connected to the equipment grounding conductor or can be attached directly to a grounded metal box if no grounding conductor is available.

Stranded wire can get frayed and spread out when tightened under a ground screw. I use a washer to cover a metal box’s entire stranded wire loop. I sometimes crimp on a fork terminal connector to connect the other end under the wiring device green screw.

OTHER GROUNDING METHODS

The grounding conductor attached to the old pancake box below using a grounding clip can only be used if a grounded BX cable or metal conduit is connected to this old box.

Grounding clips are helpful when a tapped hole for a ground screw is unavailable.

See my post about replacing old pancake boxes.

This is how to ground an outlet that does not have any grounding at all. The National Electrical Code article 250.130(C) allows you to install a separate grounding wire to the nearest water pipe or grounding electrode conductor in your home and connect it with a water pipe ground clamp or other appropriate connection.

Knowing how to ground an outlet is suitable when no ground is available. However, the work of installing a separate ground wire will be almost the same as if you were going to install all new electrical wiring. Also, I have noticed in old houses lately that whenever the old copper and galvanized water pipes get replaced, they are usually replaced with plastic pipes.

All grounding continuity is lost when a plastic water pipe is connected to a metal water line. So, if you were to run a ground wire to the nearest copper pipe in an old house, that pipe might not be grounded.

Two-prong non-grounding receptacles can be replaced with tamper-resistant grounding-type GFCI receptacles. The new outlet would have to be labeled “No Equipment Ground.” See article 406.4(D) in the National Electrical Code for specific information.

Visit my post regarding the replacement of GFCI receptacle outlets.

Below is a grounding method that I have used many times when possible. I strip some extra wire from the cable and use the excess for pigtails between outlets. I keep the ground wire long and loop it from one green screw to the next green screw without cutting. This does not appear to violate article 250.148(B).

I have used the method depicted below for grounding metal boxes for decades. Not anymore. The feed wire grounding conductor is wrapped around the green screw with a tail left for splicing to all other grounds in the box.

This technique has been outlawed in the 2020 National Electrical Code article 250.148(C). The metal box must now have a separate grounding pigtail.

Notice the knockout seal in the center of the box. There cannot be any open holes in an electrical box. The knockout seals are an approved method for filling the holes and are removable.

Under limited circumstances, a Flexible Metal Conduit (Type FMC) can be a grounding conductor for short distances with approved fittings. Read articles 250.118(5) and 348.60. Installing an equipment grounding conductor wire is better than relying on FMC for grounding.

Liquidight Flexible Metal Conduit (Type LFMC) can be a grounding conductor under limited installation conditions with approved fittings. It is better to install a separate green wire to be used as the equipment grounding conductor. See article 350.60.

The surface metal raceway, Wiremold 500, is an approved grounding conductor. Click here to see how to ground an outlet in my example of a Wiremold 500 installation.

See some examples of bad grounding on my naughty blog post here.

Surge protection devices must be installed on a home’s electrical service, per article 230.67 in the National Electrical Code (NFPA 70, 2023). Also, read article 242. Please read my article that explains Surge Protectors and their installation by clicking here.

Visit my Link Tree for free electrical information, stickers, supplies, merchandise, and social media links.