Dear Mr. Electrician: The home inspector said my house has a lot of naughty electrical code and safety violations. How can I identify the problems and make code-compliant electrical repairs myself?

Answer: Without experience and knowledge, you will be unable to identify all of the naughty electrical code and safety violations or make proper repairs.

NOTE: Some text links below go to applicable products on Amazon. As an Amazon Associate, I earn from qualifying purchases. Using my links helps to keep this website FREE.

Identifying and implementing safe work practices is essential, even if you work alone in your home.

Repairs can sometimes be more challenging than installing new things. You must work within existing spaces and finished walls and be much neater doing the work.

Do a lot of research. Read books, and watch videos from reputable producers such as This Old House. Each building code violation will require a different code-based solution.

Talk to a few electrical contractors. Ask a lot of questions. You may be able to get an idea of what corrections need to be done and maybe how.

Sometimes other trade skills are needed in the course of doing electrical work. The electrical trade learning curve is great with a combination of classroom training and several years of working under experienced people. In addition, an investment in specialty tools is required.

The photo at the top of this page is an example of a metal armored cable spliced inside a plastic electrical box. Metal armored cables must be terminated in metal electrical boxes. The metal armor of the BX cable is the grounding conductor. It maintains grounding continuity by being connected with the correct tightly installed BX connector.

The Romex cable grounding conductor is then attached to the metal box using a 10/32 machine screw. The electrical box must also have a blank cover on it.

EXAMPLES OF NAUGHTY CODE AND SAFETY ELECTRICAL WIRING

I have made many repairs to DIY wiring and observed many code violations and poor installation methods. Below is a partial list of common electrical wiring mistakes I have encountered.

Please note that a homeowner does not always do DIY-type wiring. It is often done by other contractors and handypersons who are not qualified or licensed to install electrical wiring. Homeowners should be aware of who is doing electrical work in their homes. Insist on getting permits for any new electrical installations.

The wife called me after her husband tried to install a ceiling fan. Above is what I found when I arrived. This was the first time I had seen an electrical box installed upside down in the ceiling.

The homeowner removed the existing builder-installed plastic electrical box, but he did this instead of buying an old work fan brace and box that would have fit through the existing hole. The ceiling fan support bracket was attached to the back side of the electrical box.

That electrical box was not rated for fan support, and installing it upside down made it inaccessible.

See my posts about ceiling fans for more helpful information.

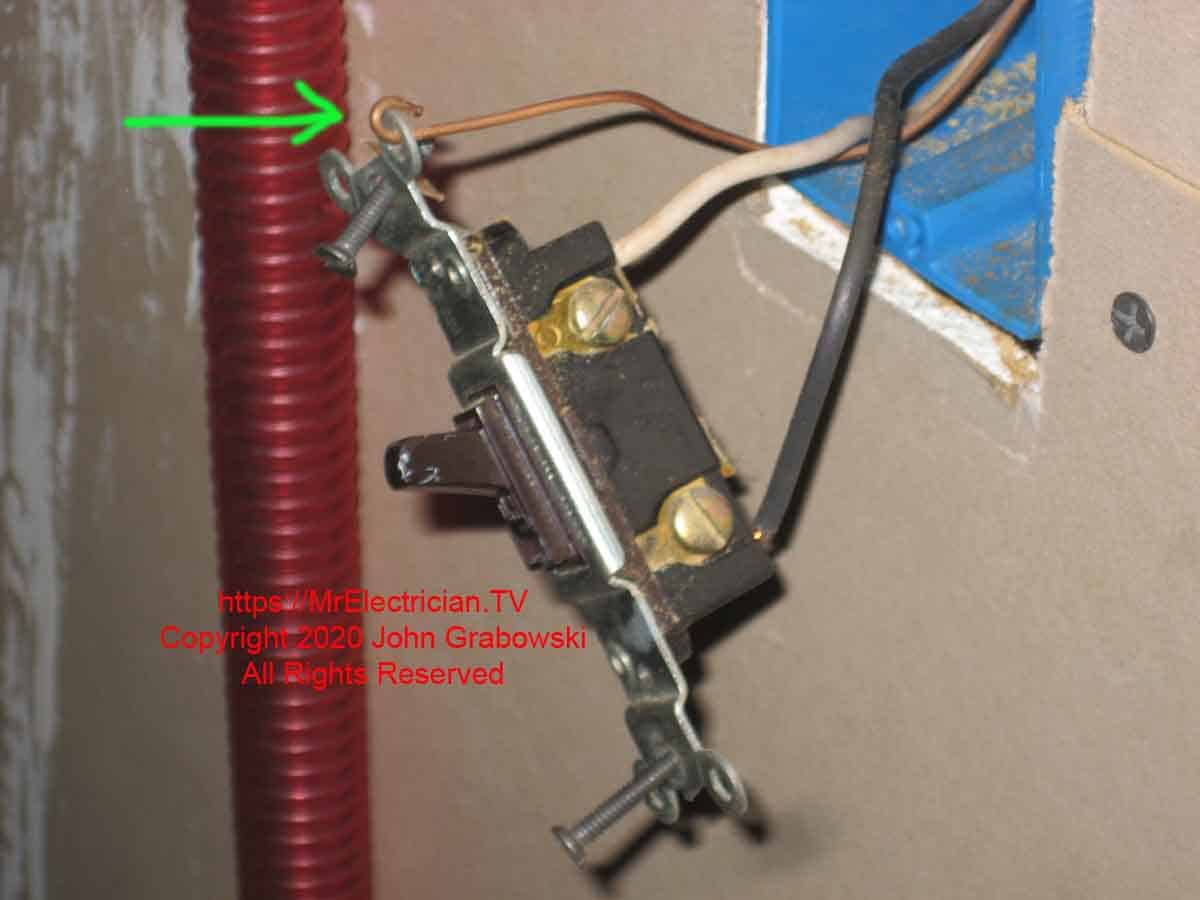

In the photo above, I found this wall switch was improperly grounded by just looping the grounding conductor around the ear of the device. This old switch did not have a green ground screw on it. I replaced it with a switch that did have a ground screw.

See my post about grounding outlets and switches, depicting various methods of grounding electrical boxes and devices.

Not reading or consulting the newest edition of the “National Electrical Code” (NFPA 70). It is imperative that electrical wiring be installed safely. The NEC is published and updated every three years to stay on top of the ever-changing consumer and industry needs while providing the latest rules and guidelines for safe electrical installations.

Please be advised that in addition to the “National Electrical Code,” some towns, cities, and states have their own electrical codes that must be followed. Contacting your local building department to see what codes are in effect is a good idea. Other codes may apply to electrical installations, such as fire, energy, sound, building, etc.

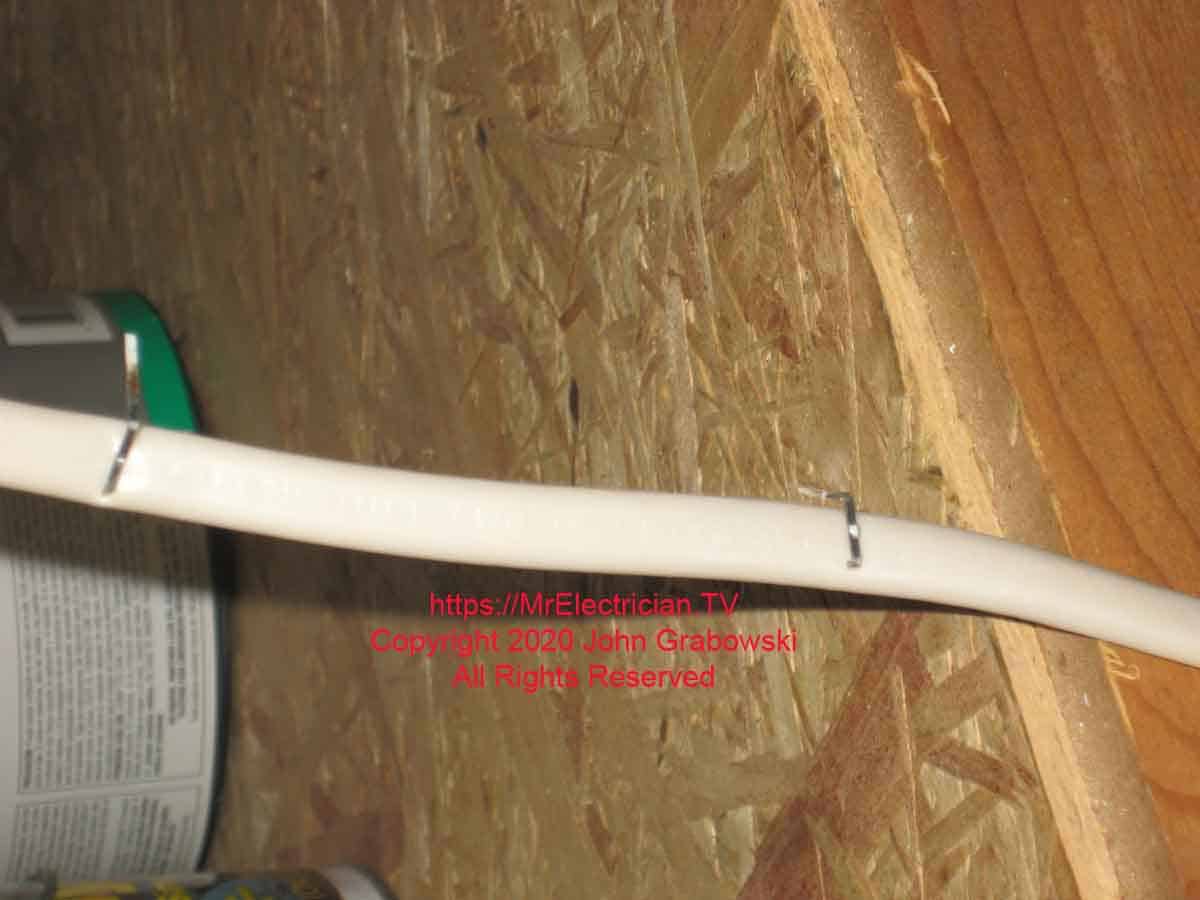

The non-metallic jacketed cable depicted above was securely fastened to the joists. However, the staples went through the cable instead of around, creating a short circuit that tripped the circuit breaker off.

Not considering the safety of your actions. Working with electricity and wiring can be hazardous to your health. At the very least, goggles, gloves, and a disposable dust mask should be part of your toolbox. Good high-back work shoes with steel toes are what many construction workers wear on their feet for comfort and protection. You should consider the same. Consult OSHA Publication #1926 for the guidelines for safety in the construction industry.

In addition, others will most likely use the wiring you install. It is important to ensure their safety with minimal risk by following the building codes during installation.

See my article about safely working around your home.

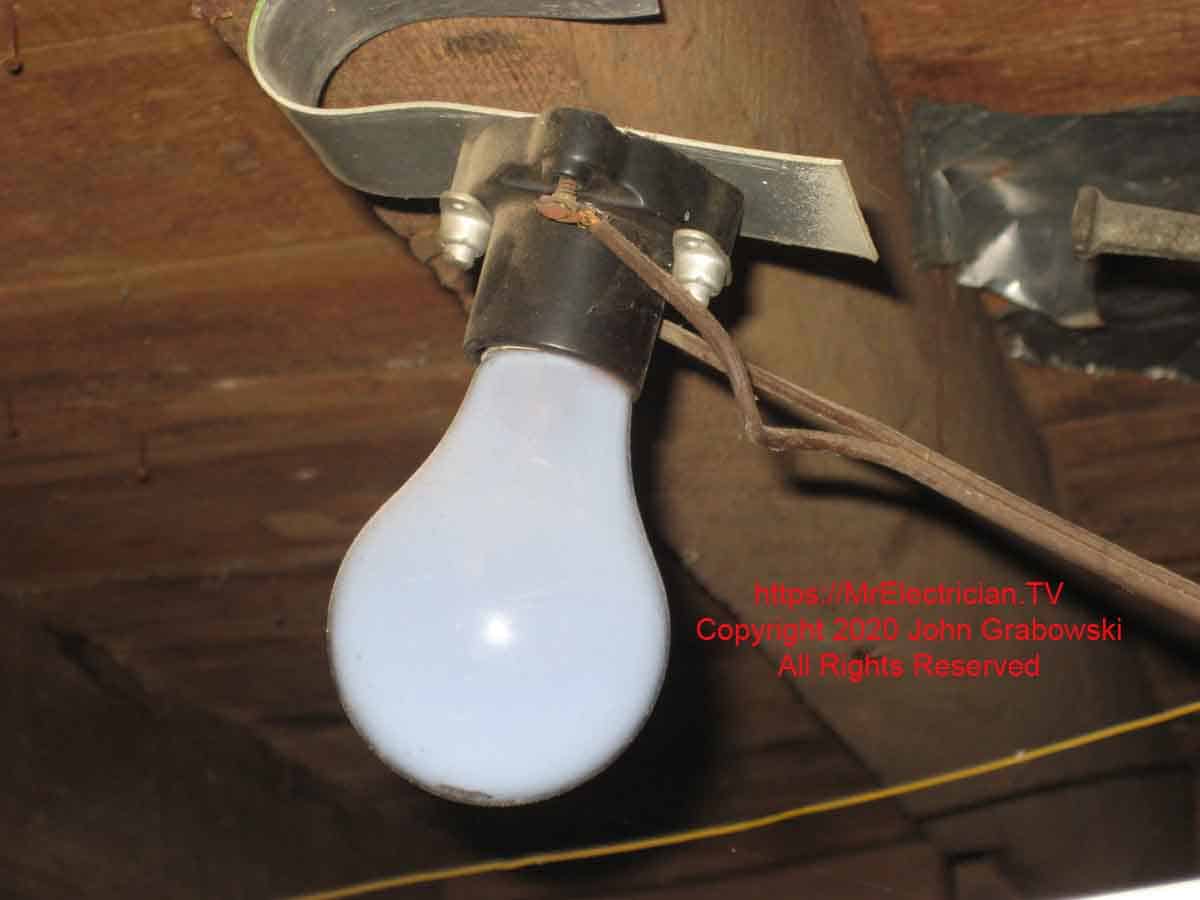

The light bulb socket in a low ceiling basement above was plugged into a switch-controlled light socket with a screw-in adaptor. The wire was a lamp cord not rated for a permanent installation, and the live screw terminals were exposed and loose! I removed this.

A better installation for a simple light would be using an approved cable such as Romex or BX and an electrical box with a keyless light socket.

Not getting an electrical permit or having your electrical installation inspected. There are a few arguments for NOT getting a permit or having an inspection performed, such as the government infringing on the rights of individuals or refusing to pay the cost of the permit and inspection. SAFETY is paramount and quashes all arguments against permits.

If you are a non-professional doing an electrical installation in your home, you need confirmation that the work is done in a safe and workmanlike manner. The safety and well-being of you, your family, and your home are at stake.

Doing the job right includes a permit and inspection by your local building department or whatever authority has jurisdiction over home improvement in your community.

Sometimes owners in a community have an additional authority, such as a homeowners association or management company, that must be consulted before any work is performed.

Someone wanted a wall switch for this light socket, so they fished a lamp cord into the ceiling and connected it to a switch. The socket was screwed directly to the drywall ceiling. There was no octagonal electrical box. In addition, the conductor that was switched was the neutral, not the hot wire as required.

Installing an undersized switch or outlet box to accommodate many wires. As the National Electrical Code describes, each electrical conductor requires a certain volume of space in electrical boxes. The required cubic inch amount varies according to the wire’s size and if any wiring devices, such as switches and outlets, are installed in the box.

Consult article 314 and table 314.16(A) and table 314.16(B) in the “National Electrical Code” (NFPA 70) for more information.

Cutting the wires in the outlet, switch, and junction boxes too short. Conductors should be long enough to extend past the outside edge of the box at least three inches. Read article 300.14. Longer conductors make it easier to work on them. If there is not enough room to push the wires into the box comfortably, you may need a bigger box.

Not grounding metal boxes properly. Anything metal that carries electrical conductors or contains wiring devices must be grounded. If you use type NM-B cable, it contains a separate bare copper grounding conductor. This must be secured to a metal box using a separate machine screw.

Type AC cable (BX) has metal armor around the wires for protection. That metal armor is also the grounding conductor for the BX cable. The proper connectors must be used and installed wrench-tight to ensure ground continuity.

A cover screw or a screw that secures the box to a wall or ceiling cannot be used to attach the grounding conductor. All metal boxes have a tapped hole for a 10/32 screw (#10 machine screw with 32 threads per inch). Use that hole and a 10/32 green grounding screw to ground the box. Read section VI in Article 250.

There were several electrical outlets in this room wired like the one above. The BX armored cable was not cut cleanly, nor did it have any bushings. Consequently, the armor created a short circuit when it cut into the hot wire.

In addition, there wasn’t a good ground connection because a clamp or connector was not used to secure the cable armor tightly to the box. Below is the solution.

The armored cables above were trimmed back using my BX cutting pliers, and anti-short bushings were inserted into the cable. A clamp inside the box will lock the cables, ensuring ground continuity.

For ease of installation, it is better to leave the BX armor out of the box a little until the outlet box is pushed into the wall. Then the wires are pulled into the box, and the cable armor comes into the clamp and is tightened. The cable armor must be in tight contact with the metal box to ensure grounding continuity.

Not locating underground utilities before you dig. Call 811 to arrange a FREE markdown of your underground utilities before you dig anywhere on your property.

811 is a national hotline that will contact all of your local utility companies and arrange for them to come out and locate and mark where your water, gas, electric, telephone, and cable TV services are located.

Using an extension cord for permanent wiring. Different types of wires and cables are approved for various purposes. Cords approved for portable and temporary use are not to be used as permanently installed wiring.

The extension cord insulation has different properties and characteristics, making it unsuitable for long-term installed usage. Sometimes, the insulation will eventually dry out and break off, exposing the bare copper conductors. Read articles 310, 400.7, and 400.8 in the “National Electrical Code” (NFPA 70).

Instead of installing an electrical outlet, someone connected a Romex cable directly to a plug in the photo above. This was covered in several layers of electrical tape when I found it.

Using NM-B cable underground. You must use cable and wire rated and labeled for underground use, even in a conduit. Moisture still condenses inside an underground conduit and can cause problems leading to the failure of the cable.

Do not use NM-B in the ground directly or in a conduit buried in the ground. Use type UF cable for direct burial underground wiring or THWN conductors inside a buried underground conduit. Article 334 covers NM-B cable, and UF cable is under Article 340.

Wiring under-cabinet lights wrong. A common type of under-cabinet light sold in retail stores is a lamp cord with a plug attached to the fixture. Using that light by plugging it into an electrical wall receptacle is safe.

Cutting the plug off, installing the lamp cord into the wall, and controlling the under-cabinet light using a wall switch are unsafe.

The proper method is to have an electrical receptacle controlled by a wall switch or use under-cabinet light fixtures approved to be hard-wired directly. These can be purchased at a lighting store or an electrical supply company. There are also low-voltage options for under-cabinet lighting with less stringent code requirements for wiring.

Splicing wires together without a junction box. I see this a lot. Two or more cables are spliced together using wirenuts, usually, but there is no junction box. The wires are just hanging out, sometimes in an attic, other times in the basement, or buried inside a wall.

Wires must be spliced inside of a junction box. See article 314 in the “National Electrical Code” (NFPA 70) to determine the correct size junction box based on the number and size of conductors you plan on splicing.

Calling an electrician to install wiring AFTER you have painted and decorated. This isn’t a code or safety violation, but it is not a good idea. Electrical wiring needs to be installed inside the walls and ceilings. Therefore installing the wiring is first before finishing the walls and ceiling.

Sometimes holes must be made in the walls and ceiling to install wiring for receptacles, switches, and light fixtures. Call an electrician BEFORE you do any painting and decorating if you plan to have lighting, outlets, and switches installed. Form follows function.

The plug on the factory-installed short cord connected to the above-hanging fluorescent light fixture was cut off, and the wire was connected directly inside the outlet box.

The green arrow points to the grounding conductor from the Romex cable. It was never connected and instead just doubled back out the connector. The BX cable was hanging in the air without staples or other support.

To help keep this website free, please use this Amazon link for your purchases. As an Amazon Associate, I earn from qualifying purchases.

Click here for a FREE copy of my book “Almost Everything You Need To Know To Repair a Bathroom Exhaust Fan In Your Home.”

Get your required “Emergency Disconnect, Service Disconnect” labels and stickers to satisfy the 2023 National Electrical Code requirements in article 230.85(E)(2) by going to my Redbubble Shop here.

Visit my Link Tree for social media links, free electrical information, and unique products.