Dear Mr. Electrician: What tool reviews have you written for products you have used?

Answer: Tool reviews of my tools are down below.

NOTE: Some text links below go to applicable products on Amazon. As an Amazon Associate, I earn from qualifying purchases. Using my links helps to keep this website FREE.

There are several tools I have grown to love working with because work goes so much better with the proper tools. Having the right tool for the job increases productivity and helps ensure the work is done correctly. My tool reviews are based on my actual use of the tools as part of my work as an electrician.

I can confidently say that not everything is manufactured to the same standards, and identical services from different companies don’t always match up. Now more than ever, shopping around to find the best deal or product for you and your needs is essential. Read many tool reviews.

One of my favorite tools from my young electrician days that I still use occasionally is my Bright Star 1618-CT continuity testing flashlight(s). See the photo at the top of this post. They are convenient for checking fuses and incandescent or halogen light bulbs. They are also suitable for identifying wires on dead circuits or wires that are shorted together.

The flashlight has a jack in the back screw cap that a set of alligator leads can plug into. After the leads are inserted, the flashlight will only light when the two alligator clips are connected.

I saw LED upgrade kits for these flashlights in a store, so I bought one. The original PR-type incandescent bulb was not that bright.

The original manufacturer no longer makes these flashlight continuity testers, but plenty of other types of testers are available.

I have always been a tool nut, and when I was much younger, I would buy tools because I liked them and hoped to be able to use them one day. I have many tools in my collection that I have never or hardly ever used.

My current advice is to wait until I need the tool unless a bargain buying opportunity comes along that is too good to pass. My tool reviews are based on my experiences using them while working as an electrician.

TOOL REVIEWS

My three Ideal voltage testers have been with me for a long time. The model on the right also has a built-in continuity tester.

I have several small pry bars that come in handy during remodeling jobs.

Another handy tool to have is a thread-restoring file. Suitable for when you have to cut some screws or bolts.

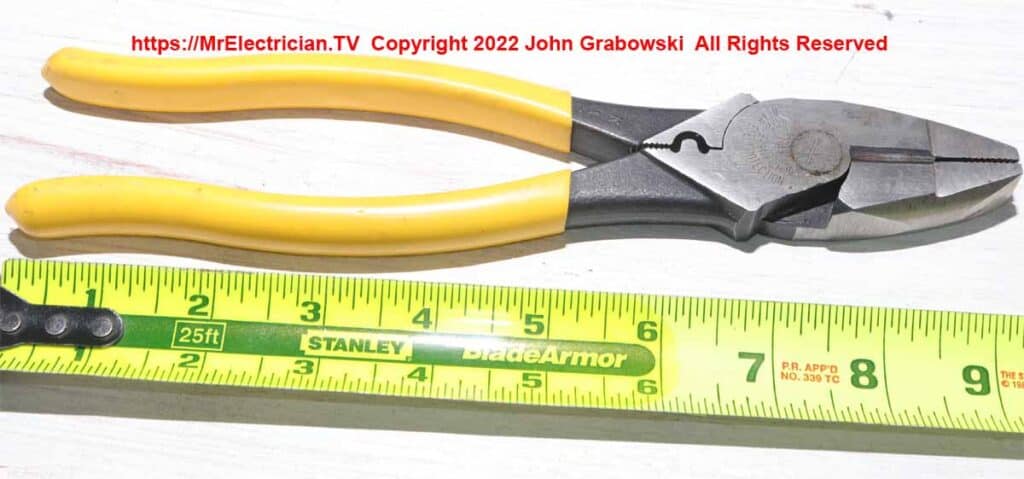

I love my Klein Lineman Pliers with the built-in crimper.

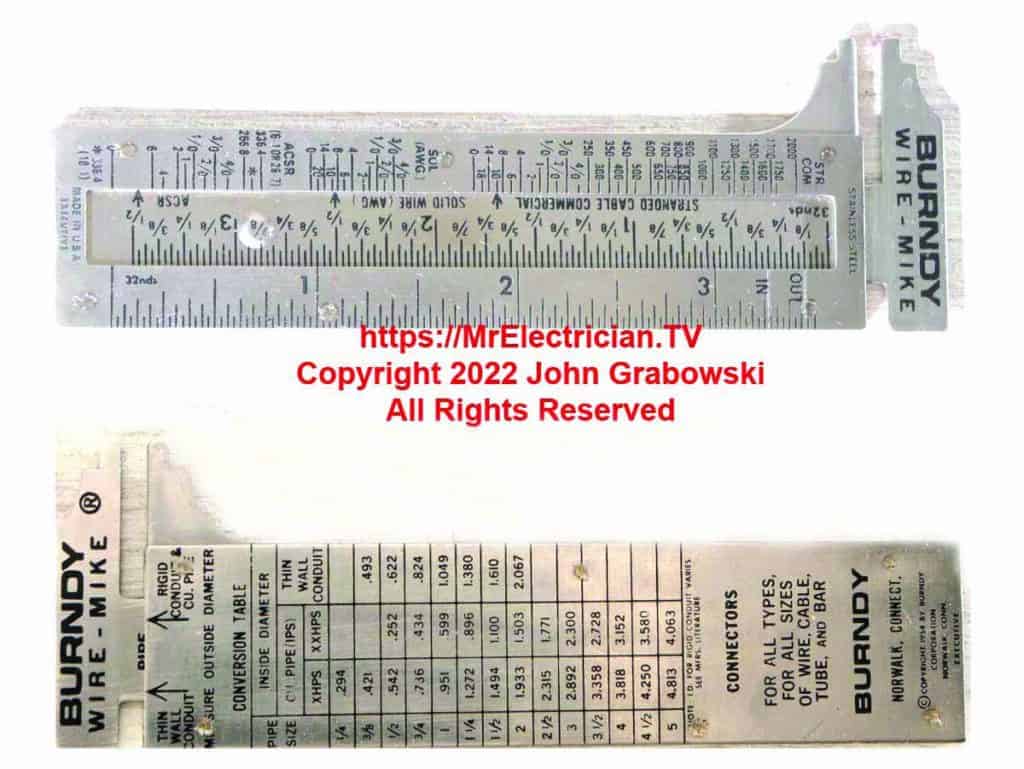

If you want to give a gift to an electrician, this would be a good one. A Burndy Wire-Mike is suitable for determining wire and conduit sizes.

I initially bought the protractor level with a magnetic base to bend the conduit.

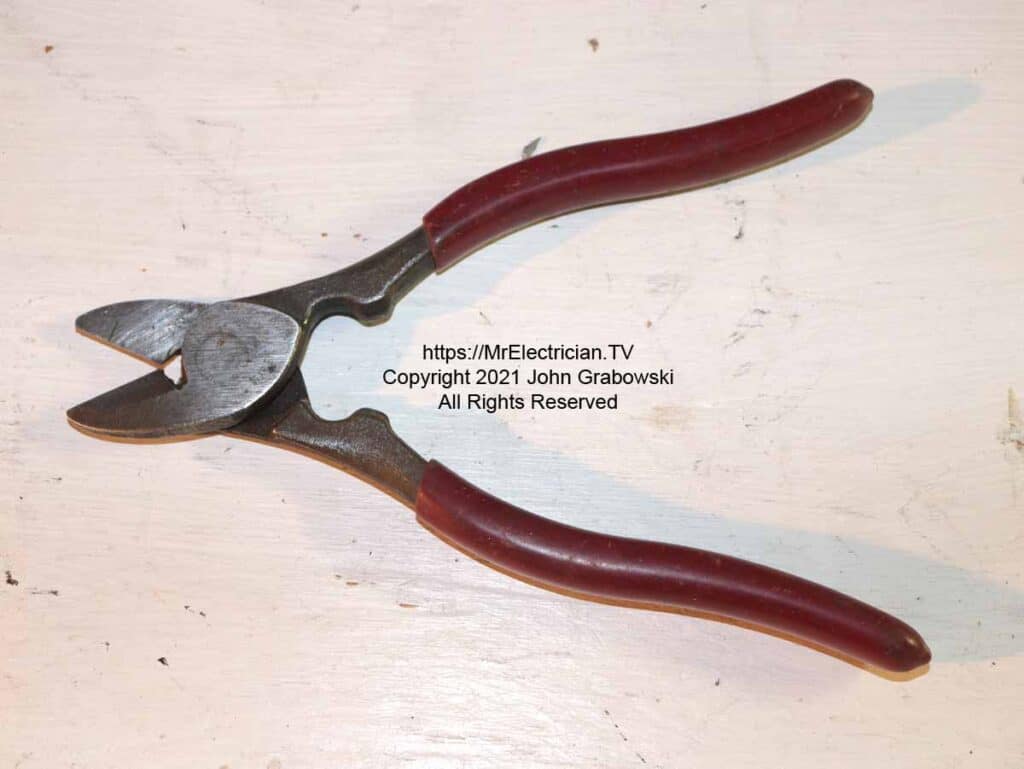

I have used BX cutters since I was a kid. Working with my dad in the 1960s, we mostly installed BX cables. A hacksaw and these BX cutters were used to cut and trim BX cable. After trimming, the round opening below the jaws on the BX cutters is used to reshape the BX armor. I have found that the BX cutters are also useful for cutting sheet metal.

In my blog post about removing concentric knockouts, I demonstrate how I cut the knockout rings with my BX cutting pliers and my Knipex high-leverage diagonal pliers.

I don’t remember how I came to purchase my Knipex high-leverage diagonal pliers, but I have never regretted it. I was amazed at the many things the Knipex diagonal pliers would cut. My most popular use is cutting the nails from electrical boxes I am removing.

Some of my blog posts include photos of my Knipex high-leverage diagonal pliers. My post about converting a switched outlet to hot at all times is one example of where I cut nails to remove a switch box.

I met the inventor of the Roto-Split BX cutting tool at an electrical trade show many years ago. I fell in love with the tool as soon as I saw it. His wife told me how they would work all hours in their garage assembling the parts for each tool and then packaging them.

Now, several manufacturers have their variations of the Roto-Split. I think the original inventor sold his company to a larger organization. The Roto-Split makes cutting BX cable up on a ladder or in odd or confining positions much easier.

Before Seatek came out with the Roto-Split armor-cutting tool, I used a hacksaw or my Klein BX cutters to cut the armor. For the hacksaw, I would have to put my foot on the BX coil on the floor, pull the tail end tight, and cut it at an angle, stopping short of nicking the wire insulation inside. Working on a ladder up in a ceiling and cutting BX cable with a hacksaw was a learned necessary skill.

If I wanted to cut the armored cable with my Klein BX cutting pliers, I would have to snap the armor by squeezing it tightly or twisting it until I opened a small loop where I wanted it cut and slip the cutters in the loop to cut and trim. Although this worked well, it tired my hand muscles after doing it all day long.

To use the Roto-Split, insert a BX cable in the side groove. Tighten the set screw where the cable should be cut or the armor stripped back. Squeeze the Roto-Split with one hand while turning the crank handle with the other hand. The small circular blade will cut the metal armor to the correct depth without harming the wires inside.

The Roto-Split blades last a long time and are easy to replace.

I first saw ReceptXtenders while perusing the electrical aisle of a big store. I was browsing to see if the store had any unique products that I might find helpful. I saw the ReceptXtenders and bought one in each size. Though they work very well for their intended purpose, I came up with an idea on how to use them that saves me a lot of work and aggravation.

I have worked on many kitchen renovations as an electrical contractor. I must install, move, or adjust electrical outlets and switches during the remodeling process. After putting the electrical switch and outlet boxes in the wall with wiring, I usually don’t return to the job until the walls are finished.

In the past, when I went back to finish wiring and install switches and outlets, I would often find that the electrical boxes were partially covered with ceramic tile, stone, or some other wall covering. The installers thought they left enough room for me, but they didn’t. I had to buy a RotoZip Spiral Saw and tile-cutting bits to enlarge the tile and stone wall openings neatly. This was time-consuming and made dust.

What I do now is install the deepest ReceptXtenders on my roughed-in outlet boxes so that they will be extended past the finished wall. When I return for my finished work, I remove the ReceptXtenders, and the electrical box wall openings are the same size as the electrical box.

The tile installers had cut their tile to the edge of the extender. The new outlet boxes I installed will be flush with the finished wall, and the existing outlet boxes will get the proper depth ReceptXtender to support the switch or outlet.

Here is an example of a kitchen I worked on using the ReceptXtenders. The above is more of a product than a tool review.

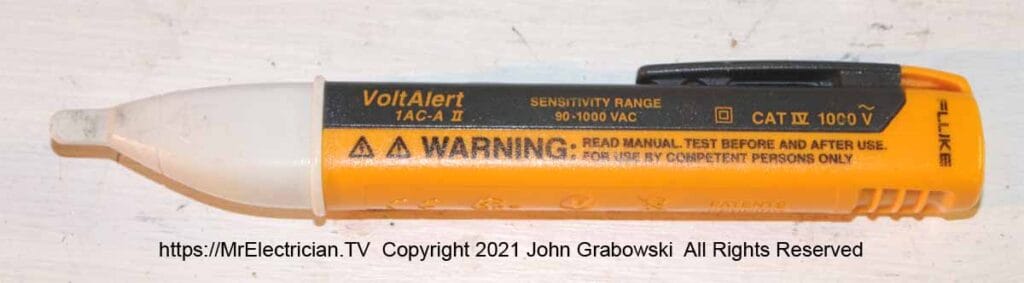

I have tried some non-contact voltage detectors from different manufacturers, but the Fluke Volt Alert works best for me. The problem with the other non-contact detectors was with false readings. The readings on older insulated wires, especially cloth-insulated conductors, were often erroneous. The Fluke model doesn’t seem to have a problem with old insulation.

The SDS Max ground rod driver pounding in ground rods saves labor and your hands and wrists. The cost was minimal compared to the savings. In this blog post of mine, you can see how the tool is used. This will work on all SDS Max rotary hammers and Hilti TE-Y.

My Klein 627-20 six-in-one tapping tool is a standard pouch item. It is so helpful when re-tapping holes on switch and outlet boxes. It is convenient for cleaning out threaded holes with joint compound or paint. The taps are replaceable should they wear down or get broken. I usually buy replacement taps at my local electrical supply company.

My first headlamp was a lightweight Zenon bulb model. It worked well enough to get me hooked on wearing a headlamp. When I worked for my dad, I did what he did when light was needed while working. We would stick our Brightstar double D battery incandescent flashlights (At the top of this post) between our neck and shoulders and tilt our necks to hold them in place while we worked. Talk about a pain in the neck.

The Princeton Tec headlamp in the middle is watertight and has a flashing feature. The AA three battery pack is on the rear of the headband with a durable cord connecting the light. Princeton Tec also sells replacement headbands.

The Coast headlamp on the right has a separately switched red and green light, and the leading light has a focusing lens from spot to flood. AAA batteries are inside the headlamp.

The Duracell model on the left also has a red light, and it has separately controlled lights on the sides and bottom, which are excellent when you are with other people as the light is not in their faces when you talk to them. Good for camping. Uses three AAA batteries.

I keep a few Duracells at home for when the power goes out. All of the headlamps above have multiple brightness settings.

I first heard of oscillating multi-tools on some newsgroups that I follow. Then I watched some videos and a Fein Multimaster infomercial. I thought it was a very excellent tool. I had a job coming up where I thought a multi-tool would be helpful, so I bought a cheap electric one to try it out.

I was convinced that I bought a handy tool the first time I used it. I found so many other uses after that I kept it on my truck full time. The cheap one I originally bought worked well, and I still have it. However, it was a little on the heavy side.

I picked up a Milwaukee cordless multi-tool from a store display and realized what a difference there was in weight. I bought it on the spot. I bought a second one when I got busy and had a bigger crew. They paid for themselves very quickly.

One caveat I don’t like about the multi-tools is that many of the blades are proprietary to the particular tool manufacturer. Not all oscillating multi-tool blades are interchangeable like reciprocating saw blades are. Adapters are available. I make sure that I always buy the correct blades.

Click to see my blog post about Electrician Tools.

For ideas and suggestions for setting up your woodshop or workshop at home on a budget, click my blog post here.

This website offers tool reviews of professional tools along with handy tips.

To help keep this website FREE, please use this Amazon link for your purchases. As an Amazon Associate, I earn from qualifying purchases.

Click for a FREE copy of my book “Almost Everything You Need To Know To Repair a Bathroom Exhaust Fan In Your Home.”

Get your required “Emergency Disconnect, Service Disconnect” labels and stickers to satisfy the 2023 National Electrical Code requirements in article 230.85(E)(1) and (2) by going to my Redbubble Shop here.

Visit my Link Tree home page for my social media connections and other links.