Dear Mr. Electrician: What is required for a generator sub-panel installation? I want a generator sub-panel for circuits in my house, such as the furnace, the sump pump, and the refrigerator.

Answer: Requirements for a generator sub-panel installation vary, and several types of generator sub-panels are available.

NOTE: Some text links below go to applicable products on Amazon. As an Amazon Associate, I earn from qualifying purchases. Using my links helps to keep this website FREE.

Some types of generator sub-panels come pre-wired from the factory. It is just a matter of connecting the flexible conduit to the main electrical panel and then making all the electrical connections per the instructions. That type of sub-panel can only be used directly adjacent to the main electrical panel and has limited circuits.

Another type of installation utilizes a standard electrical load center as a generator sub-panel for some previously selected circuits to be powered when the generator is on. Below are photos of a generator sub-panel installation using a Square D generator sub-panel, which included two main breakers, an interlock kit, and a circuit breaker hold-down kit.

As with any new electrical installation, the town building department must issue an electrical permit. Submit a copy of the sub-panel instructions and specifications with your permit application. Also include information about an interlock kit, if one will be used, and where the sub-panel will be located.

If you use an interlock kit made by a third party, ensure it has a testing laboratory approval such as Underwriter’s Laboratories (UL). Interlock kits made by the electrical panel manufacturer will have this approval.

If the installation is a little out of the ordinary or you have questions about code compliance, you can include photos of the new generator sub-panel location with your permit application and the existing electrical service and main electrical panel.

I usually include a one-page typed “Scope of Work” that briefly describes the work to be done and some of the materials used.

It is best to provide as much clear and concise information as possible with your permit application so the inspector fully understands the work being done beforehand. It is better to find out ahead of time if the installation will be code-compliant rather than after the work is done and your work fails inspection.

Some applicable articles from the National Electrical Code concerning the installation of generator sub-panels are 210, 230, 250, 300, 310, 314, 334, 445, and 702.

PORTABLE GENERATOR SUB-PANEL INSTALLATION

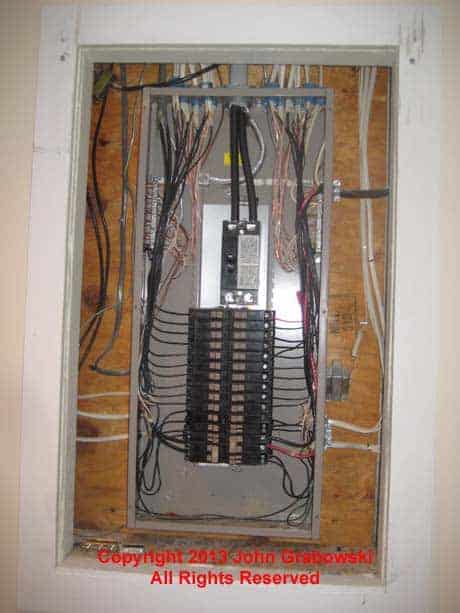

I have found that some finished basements have made the main electrical panel inaccessible for future renovations and sometimes even for repairs. The Cutler Hammer load center depicted here was boxed in by the wall erected in the basement. Fortunately, it was not completely enclosed.

I could remove the circuit cables to be relocated into the generator sub-panel from the top of the main electrical panel and fish them into the ceiling above. I had enough slack on the Romex cables to bring them into two 4 11/16″ square junction boxes.

Two large junction boxes were installed close to the main electrical panel in the accessible ceiling so that the circuit wires removed from the main panel could be spliced and extended to the new generator sub-panel. I installed new cables to the generator sub-panel from the ceiling-mounted junction boxes,

CLICK HERE To See All Of The Generator Sub-Panels That Amazon Has For Sale

The view above inside the wall shows the right side of the main electrical panel. The camera angle is from inside a basement utility closet where the new generator sub-panel will be located. The right side of the Cutler Hammer load center was open all the way to this closet. I installed a 10/3 Romex cable through that space to feed power to the new Square D generator sub-panel.

The joists are prefabricated I-Joists with pre-punched holes every 12″ for wires and pipes.

Because the junction boxes are metal, they must be grounded using a 10/32 ground screw with a grounding pigtail connecting to all the grounding conductors in that box. All grounding conductors are joined by twisting and finished with a wire connector.

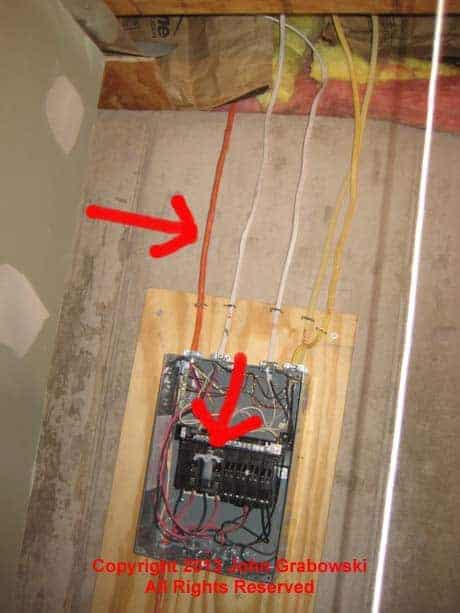

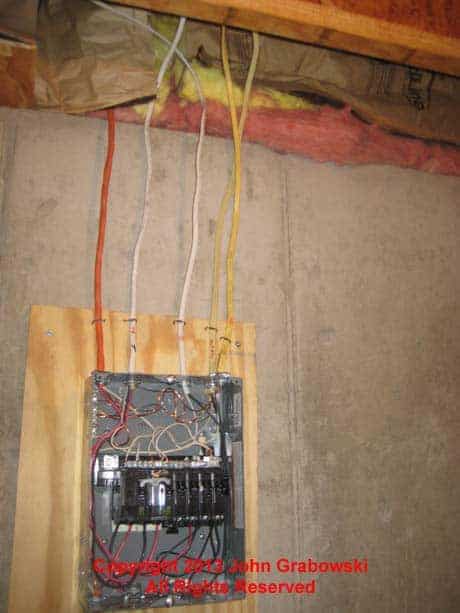

The new cables were installed across the ceiling and brought to the top of the generator sub-panel. There was a lot of room in the ceiling, and a plywood board was attached to the concrete foundation wall to mount the sub-panel. I used an electric hammer drill to make 1/4″ diameter holes in the concrete and then used plastic anchors and #12 sheet metal screws to secure the board to the concrete.

In the photo above, the upper red arrow points to the cable feed from the generator inlet mounted outside the house. The other red arrow points to the interlock device attached to the generator circuit breaker.

An interlock device is needed on the generator sub-panel to prevent the utility company’s power from being on at the same time as the generator. The main utility power circuit breaker and the generator power circuit breaker must be secured to the electrical panel so they cannot easily be removed or pop out independently.

The circuit breaker panel manufacturer often has a circuit breaker hold-down kit available. Read the label inside the panel to obtain a part number. This particular panel came with circuit breaker hold-downs from the manufacturer.

This Square D generator sub-panel installation differs from a regular sub-panel. The sub-panel comes with two main breakers, one for utility company power and one for generator power. They are interlocked together to prevent both breakers from being on simultaneously. In addition, each main breaker has a clamp on it holding it to the busbar as is required by article 408.36(D) in the “National Electrical Code.”

In this small 8/16 sub-panel, two Square D #PK2MB circuit breaker retainers were used to hold the main breakers in place. They are mounted on the bottom of each circuit breaker. The Square D #QO2DTI mechanical interlock prevents both circuit breakers from being on simultaneously.

Another method for larger 100 amp Square D load centers is the Square D #PK4DTIM4LA manual transfer kit which comes with a different type of circuit breaker retainer and the same mechanical interlock.